- When the single parting surface injection mould is opened, the moving die and the fixed die are separated, and the plastic parts are taken out, which is called the single parting surface mould and the double plate mould. It is the simplest and most basic form of injection mould. It can be designed as a single cavity injection mould or a multi-cavity injection mould according to the need. It is the most widely used injection mold.

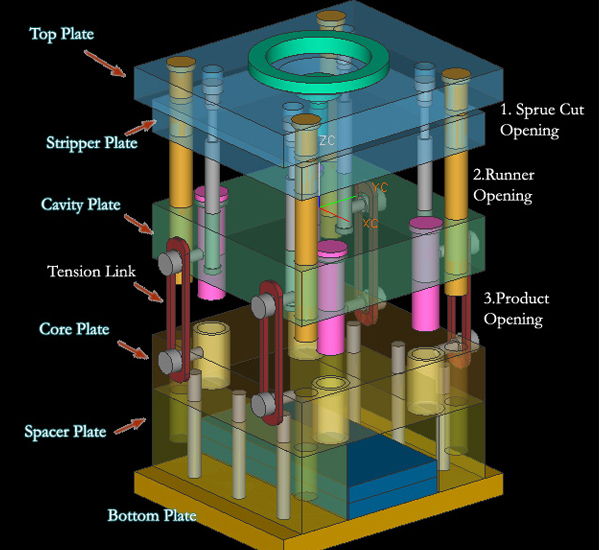

- The double parting surface injection mould has two parting surfaces. Compared with the single parting surface injection mould, the double parting surface injection mould adds a movable middle plate (also called movable gate board) in the fixed part of the mould. It has a gate, runner, and other parts and components needed for a fixed mold, so it is also called a three-plate injection mould (moving template, middle plate, fixed template). It is often used for injection molds with single or multiple cavities that point gate feed, when opening a mold, The intermediate plate is separated from the fixed template at a fixed distance on the guide column of the die to remove the castable system between the two templates. The injection mould with double parting surface is complex in structure, high in manufacturing cost and difficult in parts processing, so it is not generally used in the molding of large or super large plastic products.

- Injection molds with lateral parting and core-pulling mechanism. When plastic parts have side holes or side recesses, lateral moving cores or sliders should be used. After injection molding, the dynamic die moves a distance down first, then the inclined section of the bending pin fixed on the fixed template forces the slider to move outwards. At the same time, the push rod of the demoulding mechanism pushes the push plate to make the plastic part take off from the core.

- Because of some special structure of plastic parts, injection molds with movable forming parts require movable molding parts, such as movable punch, movable concave die, movable insert, movable thread core or ring, etc. During demoulding, you can move out of the mold together with the plastic parts, and then separate from the plastic parts.

- For plastic parts with screw threads, the injection mould can be automatically unthreaded by setting a thread core or ring that can be rotated on the mould, using the opening action or the rotating mechanism of the injection molding machine, or setting up a special transmission device. Drive screw thread core or thread ring rotation, so as to remove plastic parts.

- The injection mould without runner is the method of adiabatic heating of the runner, which keeps the plastic melt from the one cavity of the nozzle of the injection molding machine, and makes the mold take out the plastic parts without the pouring system solidification. The former is called adiabatic injection mold, the latter is called hot runner injection mold.

- The right angle injection mould is only suitable for the angular injection molding machine, which is different from other injection molds in that the feeding direction of the mould is perpendicular to the opening and closing direction of the mould. His main channel is set on both sides of the moving, fixed parting surface, and its cross section is usually the same, which is different from the mold used in other injection molding machines, the end of the main channel. In order to prevent the abrasion and deformation of the nozzle and the main inlet of the injection molding machine, replaceable runner inserts can be set up.

- In most injection molds, the demoulding device is installed on the side of the moving mold, which is advantageous to the work of ejection device in the opening and closing system of the injection molding machine. In actual production, because some plastic parts are limited by the shape, it is better to leave the plastic parts on the one side of the fixed mold, so that the plastic parts can be removed from the mold, so the demoulding mechanism must be set on the side of the fixed mold.

Jasonmould is a manufacturer of plastic molds- injection mold, die casting moulds, plastic blow molding, rotational molding, medical plastic injection molding, two shot plastic injection molding, insert molding, overmolding, metal injection molding, micro injection molding, powder injection molding, ceramic injection molding, liquid injection molding, husky injection molding, household mold, casting mold, die mold tool, custom molds, china moulds, rapid prototyping tooling, plastic prototyping tooling, punch press tooling, die and tooling for mobile/ cell phone parts, automotive parts, vacuum cleaners, rechargeable tools, telephones, copiers, computers, multimedia speakers, and many other electronic products and household appliances. And also a plastic product manufacturer- plastic parts, plastic water tank, plastic balls, plastic containers, plastic buckle, plastic anchor, plastic hanger, plastic spoon, plastic pipe fitting, plastic tumble, plastic tableware, plastic cups, plastic bottles, plastic tray, plastic cosmetic container, plastic case, plastic food container, plastic chairs, plastic caps, plastic cap closure, plastic tubes, plastic water pipes, plastic knobs, plastic tubing, plastic utility boxes, plastic racks and so on.

Jasonmould is a manufacturer of plastic molds- injection mold, die casting moulds, plastic blow molding, rotational molding, medical plastic injection molding, two shot plastic injection molding, insert molding, overmolding, metal injection molding, micro injection molding, powder injection molding, ceramic injection molding, liquid injection molding, husky injection molding, household mold, casting mold, die mold tool, custom molds, china moulds, rapid prototyping tooling, plastic prototyping tooling, punch press tooling, die and tooling for mobile/ cell phone parts, automotive parts, vacuum cleaners, rechargeable tools, telephones, copiers, computers, multimedia speakers, and many other electronic products and household appliances. And also a plastic product manufacturer- plastic parts, plastic water tank, plastic balls, plastic containers, plastic buckle, plastic anchor, plastic hanger, plastic spoon, plastic pipe fitting, plastic tumble, plastic tableware, plastic cups, plastic bottles, plastic tray, plastic cosmetic container, plastic case, plastic food container, plastic chairs, plastic caps, plastic cap closure, plastic tubes, plastic water pipes, plastic knobs, plastic tubing, plastic utility boxes, plastic racks and so on.Contact:

Contact person: James Yuan

Company name: JasonMould Industrial Company Limited

Address: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Telephone: 86-752-6682869

Email: [email protected]

Website: https://www.jasonmolding.com

18

Apr