· CNC Machining – Can be the method of choice if a full 3D CAD model is not available or if your needs require fabricating a shape from a specific material.

· Low-Cost Injection Molds – Certainly the most advanced of the prototyping options. Always with the choice in a critical application when the other options might be too limited, or if you are just ready for this step and need an immediate quantity of parts.

China Plastic Injection Molding Manufacturing Services

China Plastic Injection Molding Manufacturing Services

Djmolding is a plastic injection molding manufacturing factory with main office in Huizhou (China) to offer first class services for global companies, specialized in mold making, machinery production and turn key projects for the plastic industry. We often revise the design of products to make them cost-effective and to satisfy the request of our customers. Our company is a professional plastic manufacturer, especially for plastic cup products, and most of important, we can provide you the most competitive price for plastic products. We can send you some of products for your reference if you are interested. I am looking forward to cooperating with you in a sincerely way.

What Is Plastic Injection Mold?

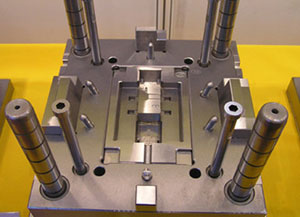

Plastic injection mold (Djmolding in china) is a tool for manufacturing plastic parts, also makes the plastic parts have full structures and precise dimensions.

Why Choose Our Company?

Why Choose Our Company?

Were you able to find a good source for plastic injection molds? You may find out there are very few Chinese manufacturers that could satisfy your companies’ needs. We are a Chinese company with our own tooling factory in Huizhou, China.  We build very precise and high quality plastic injection molds exclusively for companies from US, Canada, UK, Germany,Italy etc.

We build very precise and high quality plastic injection molds exclusively for companies from US, Canada, UK, Germany,Italy etc.

We have very good equipment including high speed CNC, mirror EDM, slow wire cut, CMM, etc. Our mold engineers are good at English and mold technologies, so our company is easy to communicate with. Feel free to let us know if you are finding a plastic injection mold maker in China.

We are a unique hybrid solution of dealing with American and European companies but getting better Chinese prices. We will be glad to review your specifications and share them with our plastic injection mold makers as well for their input. We work on a cost plus basis, we will give a very honest quotation to build what exactly you are expecting. We have a reputation for making only top quality molds and we stand behind our work. We think you will really like working with our company. We are also glad to give you the references of our many US customers that can tell you the kind of services we can offer.

Why Make Plastic Injection Molds In China?

You may hear from someone that plastic injection moulds from China are in low quality, but still there are many companies are buying injection moulds from China, some of them with big volume demands even set their own sourcing office in China. Are those companies silly? No.

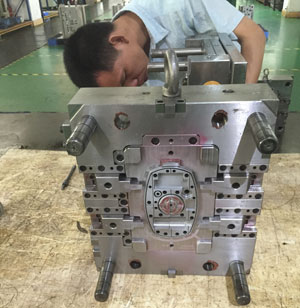

mold making

The answer is China injection mold makers can manufacture high quality moulds as good as American and Europe companies with competitive lower price,

this is why the plastic injection mold makers outside China lost their jobs to Chinese.

In China, now more and more plastic injection mold makers hire technical sales who are good at technique and English communication. As we all know, the technique requirement is the most important thing for an injection mold making project, and now a lot of Chinese mold salesman are good at CAD drawing, materials choosing and mold making process, so they can communicate with the partner engineers very well.

To make a new plastic injection mold, the 3D drawing is the first thing and then analysis how to make the mold (size, structure, material, cut down the cost and so on), so the key point is how to make the suppliers’ engineers and your companies’ requirements connection. Just like our factory, we have cooperated with a German and United Kingdom companies for more than 10 years. We works well if you have new custom mold making project next time, you can send your drawing to us to have a test.

After 30 years developing, mold manufacturing becomes to a mutual industrial in China, there are well developed industrial chain, many well trained mold makers, well educated business developing and project management employees. Despite they are paid 2/3 less than in US, they make first class mold like your mold maker did in US.

How To Select A Chinese Injection Mold Supplier?

The major reason that American and European companies source plastic injection molds in China is price, at the end of the day that is the major factor. However if we want to have a feel good discussion and ask what to look for when selecting a Chinese injection mold supplier we can look for the following:

- References — Get it from them and do your homework

- Origin of Tool Steel

- Capital investment in shop and equipment — Is it a dive?

- In place (established method) project plan that shows every aspect of build and give updates

- Quality Systems

- Validation Systems

- Knowledge of your product — Have they done this before?

- How much capability do they have — Can they do everything in-house?

- Capacity and what is it at the moment you are placing your P.O.

- Are they able to service you globally?

Mold Making Project For Plastic Molded Parts

Last year we have made 2 sets of injection molds for a US company, the part we are going to mold is made in plastics, also called ABS, it looks like a simple part, but in actual practice, a few problems comes up, our specialists solved it eventually, it is supposed something we can learn and share.

Plastic Injection Mould Product 4

Djmolding have very strict standard procedure for all injection molds coming out of our factory, after the samples are approved by customers, all molds will be set up for a few hours running to confirm stable production situation so all molds arrive at customer’s factory can gets right into smooth production.

Injection Mold Making For Medical Devices

Medical devices usually make direct or indirect contact with human body, it has high standard requirements on mold design and mold making, typical characters of medical parts are high required finish surface, particular structure design, tight tolerance, and food safe material, it is a challenge to the mold makers and injection molding companies.

Plastic Injection Mould Product 1

Custom Injection Mold Making For US companies

70% injection molds made by Djmolding are exported to US or European companies, these injection molds are usually required to be SPI Class 101, guaranteed 1 million cycles or  more, mold standard apply to US or Euro local standard so it can be easily operated and maintained.

more, mold standard apply to US or Euro local standard so it can be easily operated and maintained.

Comparing with stay-in-house-molding mold, the export mold requires a higher capability to mold maker on not just how to make the injection molds but also how to work with US companies. Here we share with you a custom mold making project we have done in our factory, we are sure there would be much more on somewhere we can do much better and achieve much more satisfaction, we summarize it, look back and move forward for better and better customized mold projects made in China by Djmolding.

Do You Really Get The Cheapest Quote Of The Injection Molds

As an engineering and manufacturing company in the China specializing in plastic injection tooling and molding we have been battling what we call ‘purchaser apathy’ ever since low labor cost countries entered the market in the 80/90’s.

It has been too easy for the manager with the sign-off to pick the ‘cheapest’ quote without understanding what quality of engineering, tooling manufacture and partnership he is getting. The specifics of what we do does not lie now in actually ‘cutting metal’ this is largely computer controlled as “metal is metal” it is the service experienced before and after that adds the value.

What we find our customer value is us telling them no they can’t do that because if they do it will impact total product quality or yes they can have an extra rib for strength in there but it will create a weld line right through their bose where the insert is going. Also find a company that has actual manufacturing on site as we do because it automatically aligns the customer and supplier goals (to make the tool as quickly as possible without compromising quality) why? Well because that’s what we have here and if we quote a customer for tooling we must make it work and work to the best of it’s ability for it to be a profitable and sustainable project.

At present, the China auto parts of high strength steel plate is also limited to structural

parts and beam parts, the tensile strength of materials used in the 500MPa or less, therefore, quickly master the high-strength steel stamping technology is Chinese automotive mold industry to be resolved important questions.

I work for an OEM company, and we generally prefer United States injection molds for the following reasons. We have China injection molds in production now, but some of our experiences tend to make us prefer to keep tooling stateside.

- Mold Design – We tend to get better designed molds in the USA. If the injection mold can be designed in the US and build in China, this has produced superior molds for us.

- Lead Times – Maybe we just had a bad experience, but one injection mold seemed to take the slow boat across the ocean. The lead time wasn’t competitive with a stateside mold.

- Mold Trial – Generally not possible to be on hand for the initial injection mold trial in China.

- Mold Modifications – We have gotten better/faster injection mold modifications when the mold was able to be sent back to the original mold maker in the USA. Sending the mold to China to be modified is cost prohibitive, so a 3rd party mold maker has to make the injection mold modifications.

The Fact Of China Plastic Injection Mold Makers

Chinese injection molds cut major corners on water, mold steels, unless you really get after them to use good mold steels. I have seen Chinese plastic injection molds that literally warp in the press because their injection molds are the softness of lead. I have seen well-made Chinese molds, but again, the materials used have been sub-par. The delay in communications is also an ongoing problem. That’s one reason I use America, UK or Italy over China — never have to worry about any of the things previously mentioned. The only reason that Chinese injection molds remain more competitively priced is the fact that the country pegs its currency to the dollar, so you never see the true cost. In the near future, the Chinese will not be able to continue pegging their currency to US dollar especially when the dollar is getting trashed by our own government. Because of this weak dollar policy, it makes everyone except China very expensive. Yet, for our European friends, it makes US made stuff cost competitive. However, even with our virtually worthless currency, I still get 25-30% less costly tooling in Portugal.