First, digital mold technology has become the mainstream direction.

The rapid development of digital mold technology in recent years is an effective way to solve many problems in the development of automotive mold.

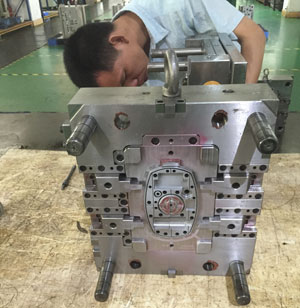

mold making

The so-called digital mold technology is the application of computer technology or computer-aided technology CAX in the mold design and manufacturing process. Successful experiences of applying computer-aided technology in automotive die and mould enterprises at home and abroad are summarized. Digital automotive mold and mould technology mainly includes the following aspects:

(1) manufacturability design (DFM), which is to consider and analyze manufacturability in design and ensure the success of the process.

(2) auxiliary technology for mold surface design, developing intelligent surface design technology;

(3) CAE assists in analyzing and simulating the stamping process, predicting and solving possible defects and forming problems.

(4) replace the traditional 2D design with the mold structure design of 3D.

(5) CAPP, CAM and CAT technologies are used in mold manufacturing.

(6) under the guidance of digital technology, we should solve the problems in the process of trial manufacture and stamping production.

Second, the position of mould 3D design is consolidated

The three-dimensional design of mold is an important part of digital mold technology, and it is the foundation of realizing the integration of mold design, manufacturing and inspection. TOYOTA, USA and other companies have realized the 3D design of the mold, and achieved good application results. Some practices abroad in the 3D design of moulds are worthy of our reference. In addition to the realization of integrated manufacturing, the three dimensional mold design is another advantage, which is convenient for interference inspection, and can carry on the motion interference analysis. It solves a problem in the two-dimensional design.

Third, the simulation CAE of stamping forming process is more prominent.

In recent years, with the rapid development of computer software and hardware, CAE simulation technology of stamping process plays an increasingly important role. In the developed countries such as the United States, Japan and Germany, CAE technology has become a necessary link in the mold design and manufacturing process. It is widely used to predict forming defects, optimize the stamping process and mold structure, improve the reliability of the die design and reduce the test time. Many automobile die enterprises in China have made remarkable progress in the application of CAE and achieved good results. The application of CAE technology can greatly save the cost of mold testing, shorten the development cycle of stamping mold, and has become an important means to ensure the quality of die. CAE technology is gradually transforming die design from experience design to scientific design.

JasonMould Industrial Company Limited, established in 2010, is a leading injection moulding manufacturer in China. JasonMould specializes in plastic mould production for household appliances, medical equipments, electronic equipments, safety equipments as well as monitoring system.

The company has over 15000 square metres factory. With plastic injection tooling divisions possessing different machinery and expertise, JasonMould offers tools from small and precise mobile phone parts to as big as automotive parts. Our tools are mainly exported to U.S.A., Europe, Japan and UK. JasonMould’s diversification strategy and full service has won compliment from customers all over the world.

Our mission is to provide our customers high quality moulding products and services. We aim to exceed our customers’ expectations of pricing, quality and on-time delivery. To achieve our mission, JasonMould:

- Commits to continually improve employee skills and efficiency,

- Provides our employees a clean and safe working environment,

- Upgrades machine technology and support equipment through a strict maintenance program, and

- Maintains customers’ tooling to its highest peak of performance

For more about custom manufacturer of plastic molding products,please visit https://www.jasonmolding.com/

Inquiry Contact:

Contact person: James Yuan

Company name: JasonMould Industrial Company Limited

Address: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Telephone: 86-752-6682869

Email: [email protected]

Website: https://www.jasonmolding.com