Failure often occurs in the use of molds, from the actual point of view, we focus on several failure modes. There are five main types:

- Failure of plastic deformation

The main reason is that the strength level of the mold material is not high; or the heat treatment process is not correct, not to achieve the best strength and toughness of steel; improper use of the die causes local overload; for hot-working mold softening at high temperature will also lead to mold thermoplastic deformation failure. Deformation failure can lead to deformation of the mold and ultimately affect the quality of the forging.

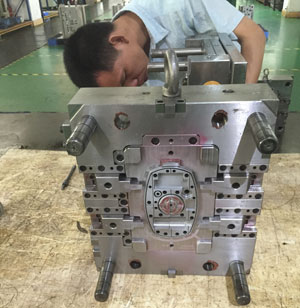

mold making

- 2.Moldswear failure

The basic reason for the failure of the mold is the friction between the mold and the billet. But the specific form of wear and the wear process are related to many factors, such as the pressure, temperature, deformation speed and lubrication condition of the mold in the working process. For hot working mold, the wear resistance decreases due to the softening of cavity surface by high temperature, and the oxide scale itself plays an abrasive role, which determines that the wear process is more complex. The wear failure of the mold mainly results in the wear of the forging mold and the accuracy of the forging.

- Fatigue failure of molds

The ultimate cause of fatigue failure is the stress concentration and cyclic load. Although the load on the mold is sometimes significantly lower than its yield strength, due to local stress concentration, under low load, microcracks still form at the stress concentration. The dies are usually in high strength and low plasticity. When the micro-cracks are formed, the micro-cracks are easy to propagate and ultimately lead to fatigue fracture under the cyclic loading of the dies.

- Cold and hot fatigue failure of molds

For the hot working mold, the surface temperature of the mold often rises to 600 ~ 900 C because of the interaction with the hot blank. In order not to reduce the strength of the mold, the mold must be sprayed with a coolant to cool it down. This cycle is a process of rapid cooling and rapid heating on the surface of the mold, and a considerable cyclic thermal stress is accumulated on the surface of the mold. The stress is finally released in the form of cold and hot fatigue, forming cold and hot fatigue cracks. As for high temperature oxidation, corrosion of coolant and friction between mould and high temperature billet, the process of cold and hot fatigue is accelerated.

- Failure under the influence of comprehensive factors

The working conditions of the mold are intricate, so the occurrence of damage events occur from time to time. Once the damage is caused, they may promote each other, and ultimately accelerate the failure of the mold.

JasonMould Industrial Company Limited, established in 2010, is a leading injection moulding manufacturer in China. JasonMould specializes in plastic mould production for household appliances, medical equipments, electronic equipments, safety equipments as well as monitoring system.

The company has over 15000 square metres factory. With plastic injection tooling divisions possessing different machinery and expertise, JasonMould offers tools from small and precise mobile phone parts to as big as automotive parts. Our tools are mainly exported to U.S.A., Europe, Japan and UK. JasonMould’s diversification strategy and full service has won compliment from customers all over the world.

Our mission is to provide our customers high quality moulding products and services. We aim to exceed our customers’ expectations of pricing, quality and on-time delivery. To achieve our mission, JasonMould:

- Commits to continually improve employee skills and efficiency,

- Provides our employees a clean and safe working environment,

- Upgrades machine technology and support equipment through a strict maintenance program, and

- Maintains customers’ tooling to its highest peak of performance

For more about custom manufacturer of plastic molding products,please visit https://www.jasonmolding.com/

Inquiry Contact:

Contact person: James Yuan

Company name: JasonMould Industrial Company Limited

Address: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Telephone: 86-752-6682869

Email: [email protected]

Website: https://www.jasonmolding.com