Most of the defects of injection molded parts are caused by the plasticization and injection stage of injection molded parts, but sometimes unreasonable design. The influencing factors include the type of injection inlet, the number of mold cavities, position and size, the design of cold/hot runner system and the structure of the product itself. Therefore, in order to avoid the product defects caused by mold design, we need to analyze the injection mold during the production.

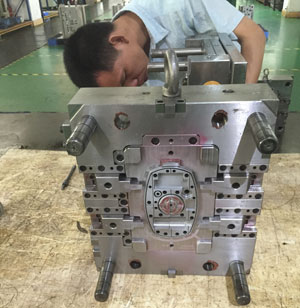

mold making

After getting the test results of the injection mold, the operator usually needs to re-evaluate the specific conditions of the mold to avoid unnecessary cost and time in the process of modification. In most cases, in order to compensate for the shortcomings in mold design, the operator may make incorrect settings without knowing, because the range of parameters required to produce qualified products is very small, once any deviation in the parameter settings may lead to the final product quality far beyond the allowable error. Range.

The purpose of injection mold test is to find out the optimized process parameters and die design. And not just to get a good sample. This is very important. Even if material, machine settings, or environmental factors change, it can ensure a stable and uninterrupted batch production environment.

JasonMouldIndustrialCompanyLimited, https://www.jasonmolding.com/ based at GuangDong Province, China was established in 2010. The company is a leading manufacturer of injection moulding and specializes in plastic moulding for use in household appliances, electronic equipment, medical and safety equipment and monitoring systems.

Contact:

JasonMould Industrial Company Limited

Address: LongGang Village, LongXi Town, BoLuo County, HuiZhou City, GuangDong Province, China

Phone: 86-752-6682869

Email: [email protected]

Website: https://www.jasonmolding.com/