(1) Tentukan jenis cetakan.

Seperti menekan mati (membuka, setengah tertutup, tertutup), casting mati, cetakan injeksi, dll.

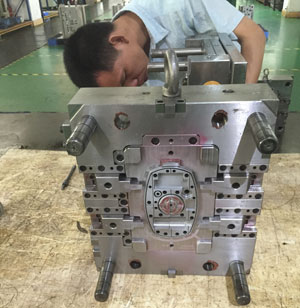

pembuatan cetakan

(2) Tentukan struktur utama jenis cetakan.

Struktur die yang ideal adalah menentukan peralatan cetakan yang diperlukan, bilangan rongga ideal, dalam kondisi yang benar-benar andal dapat membuat cetakan itu sendiri bekerja untuk memenuhi persyaratan teknis dan ekonomis dari komponen plastik. Persyaratan teknis untuk komponen plastik adalah memastikan geometri, surface finish and dimensional accuracy of plastic parts. The economic requirement of production is that the cost of plastic parts is low, the production efficiency is high, the mold can work continuously, the service life is long, and the labor force is saved.

1, Design drawings

- whether the placement parts of each mold part on the assembly drawings are appropriate, indicating whether they are clear and omissions.

2) The part number and name on the part drawing, the quantity of production, whether the part is manufactured internally or outsourced, whether it is a standard part or a non-standard part, the precision of the part matching treatment, the corrected processing and allowance at the high-precision dimension of the plastic part, and whether the material, perawatan panas, surface treatment and surface finishing degree of the mold parts are marked. Clear description;

3) The main parts of the parts, the working dimensions and the matching dimensions of the molding parts. The size number should be correct, and the producer should not be converted.

4) Check the view position of all parts drawing and assembly drawing, whether the projection is correct, whether the drawing method conforms to the drawing national standard, whether there are missing dimensions.

- Check processing performance

(all parts geometry, view drawing, ukuran, dll.) is conducive to processing.

- The main working dimensions of the auxiliary tools.

- Professional proofreading is carried out according to the self-proofing project of the designer in principle, but it should focus on the structural principle, technological performance and operation safety. When digesting drawings, we must first digest the figures, depict them according to the requirements of the national standard, and fill in all the dimensions and technical requirements. Draw after school and sign.

- Give the drawings to the designer for proofreading and signature. It is customary practice for the technical personnel concerned in the tool manufacturing unit to examine, sign and check the manufacturability before sending them to the sun.

- Compile manufacturing process cards.

The technical data produced during the period from the beginning of the design mold to the success of the mold processing and the qualified inspection, such as the task sheet, the drawing of parts, the technical specification, the assembly drawing of the mold, the drawing of the mold parts, the base drawing, the design specification of the mold, the inspection record sheet and the record of the trial and repair of the mold, are systematically arranged and assembled according to the regulations. Filing and ordering. It seems very troublesome to do this, but it is very useful for repairing molds and designing new molds later.

JasonMould Industrial Company Limited, didirikan pada 2010, adalah produsen cetakan injeksi terkemuka di Cina. JasonMould mengkhususkan diri dalam produksi cetakan plastik untuk peralatan rumah tangga, peralatan medis, peralatan elektronik, peralatan keselamatan serta sistem pemantauan.

Perusahaan telah berakhir 15000 pabrik meter persegi. Dengan divisi perkakas injeksi plastik yang memiliki mesin dan keahlian yang berbeda, JasonMould menawarkan alat dari suku cadang ponsel kecil dan presisi hingga sebesar suku cadang otomotif. Alat kami terutama diekspor ke AMERIKA SERIKAT., Eropa, Jepang dan Inggris. Strategi diversifikasi dan layanan penuh JasonMould telah memenangkan pujian dari pelanggan di seluruh dunia.

Misi kami adalah untuk menyediakan produk dan layanan cetakan berkualitas tinggi kepada pelanggan kami. Kami bertujuan untuk melampaui ekspektasi harga pelanggan kami, kualitas dan pengiriman tepat waktu. Untuk mencapai misi kami, JasonMould:

- Berkomitmen untuk terus meningkatkan keterampilan dan efisiensi karyawan,

- Memberikan karyawan kami lingkungan kerja yang bersih dan aman,

- Meningkatkan teknologi mesin dan peralatan pendukung melalui program perawatan yang ketat, dan

- Mempertahankan perkakas pelanggan ke puncak kinerja tertinggi

Untuk lebih lanjut tentang produsen kustom produk cetakan plastik,silahkan kunjungi https://www.jasonmolding.com/

Pertanyaan Hubungi:

Kontak person: James Yuan

Nama Perusahaan: JasonMould Industrial Company Limited

Alamat: Desa LongGang,Kota LongXi,Kabupaten BoLuo,Kota HuiZhou,Provinsi Guangdong, Cina

Telepon: 86-752-6682869

Surel: [email protected]

Situs web: https://www.jasonmolding.com