- Când se deschide matrița de injecție a unei singure suprafețe de separare, matrița în mișcare și matrița fixă sunt separate, iar piesele din plastic sunt scoase, care se numește matrița cu suprafață separată și matrița cu placă dublă. It is the simplest and most basic form of injection mould. It can be designed as a single cavity injection mould or a multi-cavity injection mould according to the need. It is the most widely used injection mold.

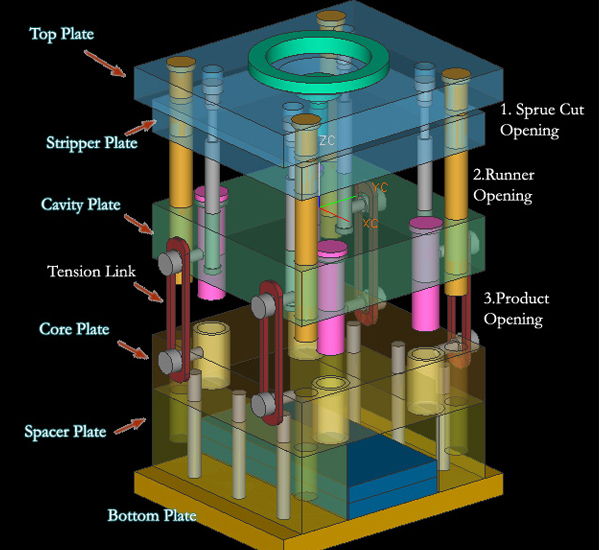

- The double parting surface injection mould has two parting surfaces. Compared with the single parting surface injection mould, the double parting surface injection mould adds a movable middle plate (also called movable gate board) in the fixed part of the mould. It has a gate, alergător, and other parts and components needed for a fixed mold, so it is also called a three-plate injection mould (șablon în mișcare, middle plate, fixed template). It is often used for injection molds with single or multiple cavities that point gate feed, when opening a mold, The intermediate plate is separated from the fixed template at a fixed distance on the guide column of the die to remove the castable system between the two templates. The injection mould with double parting surface is complex in structure, high in manufacturing cost and difficult in parts processing, so it is not generally used in the molding of large or super large plastic products.

- Injection molds with lateral parting and core-pulling mechanism. When plastic parts have side holes or side recesses, lateral moving cores or sliders should be used. After injection molding, the dynamic die moves a distance down first, then the inclined section of the bending pin fixed on the fixed template forces the slider to move outwards. În același timp, the push rod of the demoulding mechanism pushes the push plate to make the plastic part take off from the core.

- Because of some special structure of plastic parts, injection molds with movable forming parts require movable molding parts, such as movable punch, movable concave die, movable insert, movable thread core or ring, etc.. During demoulding, you can move out of the mold together with the plastic parts, and then separate from the plastic parts.

- For plastic parts with screw threads, the injection mould can be automatically unthreaded by setting a thread core or ring that can be rotated on the mould, using the opening action or the rotating mechanism of the injection molding machine, or setting up a special transmission device. Drive screw thread core or thread ring rotation, so as to remove plastic parts.

- The injection mould without runner is the method of adiabatic heating of the runner, which keeps the plastic melt from the one cavity of the nozzle of the injection molding machine, and makes the mold take out the plastic parts without the pouring system solidification. The former is called adiabatic injection mold, the latter is called hot runner injection mold.

- The right angle injection mould is only suitable for the angular injection molding machine, which is different from other injection molds in that the feeding direction of the mould is perpendicular to the opening and closing direction of the mould. His main channel is set on both sides of the moving, fixed parting surface, and its cross section is usually the same, which is different from the mold used in other injection molding machines, the end of the main channel. In order to prevent the abrasion and deformation of the nozzle and the main inlet of the injection molding machine, replaceable runner inserts can be set up.

- În majoritatea matrițelor de injecție, the demoulding device is installed on the side of the moving mold, which is advantageous to the work of ejection device in the opening and closing system of the injection molding machine. In actual production, because some plastic parts are limited by the shape, it is better to leave the plastic parts on the one side of the fixed mold, so that the plastic parts can be removed from the mold, so the demoulding mechanism must be set on the side of the fixed mold.

Jasonmould este un producător de matrițe din plastic- matriță de injecție, matrițe de turnare sub presiune, turnare prin suflare din plastic, turnare prin rotație, Cinci elemente în matriță de plastic, turnare prin injecție din plastic în două shot-uri, turnare cu inserție, supraformare, turnare prin injecție a metalelor, turnare prin injecție micro, turnare prin injecție cu pulbere, turnare prin injecție ceramică, turnare prin injecție de lichid, turnare prin injecție husky, mucegai de uz casnic, mucegai de turnare, unealtă pentru matriță, matrite la comanda, mucegaiuri din china, scule de prototipare rapidă, scule de prototipare din plastic, scule de presare, matriță și scule pentru piese de telefon mobil / mobil, piese auto, aspiratoare, instrumente reîncărcabile, telefoane, copiatoare, calculatoare, difuzoare multimedia, și multe alte produse electronice și electrocasnice. Și, de asemenea, un producător de produse din plastic- piese din material plastic, rezervor de apă din plastic, bile de plastic, containere de plastic, cataramă din plastic, ancoră din plastic, cuier din plastic, lingura de plastic, racord de țevi din plastic, cadere din plastic, Veselă din plastic, pahare de plastic, sticle de plastic, tava de plastic, recipient pentru cosmetice din plastic, Cutie de plastic, recipient de plastic pentru alimente, scaune din plastic, capace din plastic, închidere capac plastic, tuburi din plastic, conducte de apă din plastic, butoane din plastic, tuburi din plastic, cutii utilitare din plastic, rafturi din plastic și așa mai departe.

Jasonmould este un producător de matrițe din plastic- matriță de injecție, matrițe de turnare sub presiune, turnare prin suflare din plastic, turnare prin rotație, Cinci elemente în matriță de plastic, turnare prin injecție din plastic în două shot-uri, turnare cu inserție, supraformare, turnare prin injecție a metalelor, turnare prin injecție micro, turnare prin injecție cu pulbere, turnare prin injecție ceramică, turnare prin injecție de lichid, turnare prin injecție husky, mucegai de uz casnic, mucegai de turnare, unealtă pentru matriță, matrite la comanda, mucegaiuri din china, scule de prototipare rapidă, scule de prototipare din plastic, scule de presare, matriță și scule pentru piese de telefon mobil / mobil, piese auto, aspiratoare, instrumente reîncărcabile, telefoane, copiatoare, calculatoare, difuzoare multimedia, și multe alte produse electronice și electrocasnice. Și, de asemenea, un producător de produse din plastic- piese din material plastic, rezervor de apă din plastic, bile de plastic, containere de plastic, cataramă din plastic, ancoră din plastic, cuier din plastic, lingura de plastic, racord de țevi din plastic, cadere din plastic, Veselă din plastic, pahare de plastic, sticle de plastic, tava de plastic, recipient pentru cosmetice din plastic, Cutie de plastic, recipient de plastic pentru alimente, scaune din plastic, capace din plastic, închidere capac plastic, tuburi din plastic, conducte de apă din plastic, butoane din plastic, tuburi din plastic, cutii utilitare din plastic, rafturi din plastic și așa mai departe.a lua legatura:

Persoană de contact: James Yuan

Numele companiei: JasonMould Industrial Company Limited

Abordare: Satul LongGang,Orașul LongXi,Județul BoLuo,Orașul HuiZhou,Provincia Guangdong, China

Telefon: 86-752-6682869

E-mail: [email protected]

Site-ul web: https://www.jasonmolding.com

18

Aprilie