Først, digital form teknologi er blevet mainstream retning.

Den hurtige udvikling af digital formteknologi i de seneste år er en effektiv måde at løse mange problemer i udviklingen af bilforme.

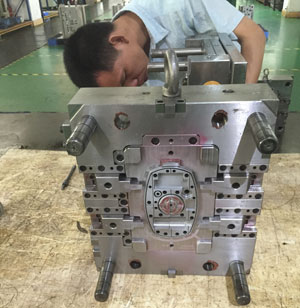

skimmelfremstilling

The so-called digital mold technology is the application of computer technology or computer-aided technology CAX in the mold design and manufacturing process. Successful experiences of applying computer-aided technology in automotive die and mould enterprises at home and abroad are summarized. Digital automotive mold and mould technology mainly includes the following aspects:

(1) manufacturability design (DFM), which is to consider and analyze manufacturability in design and ensure the success of the process.

(2) auxiliary technology for mold surface design, developing intelligent surface design technology;

(3) CAE assists in analyzing and simulating the stamping process, predicting and solving possible defects and forming problems.

(4) replace the traditional 2D design with the mold structure design of 3D.

(5) CAPP, CAM and CAT technologies are used in mold manufacturing.

(6) under the guidance of digital technology, we should solve the problems in the process of trial manufacture and stamping production.

Sekund, the position of mould 3D design is consolidated

The three-dimensional design of mold is an important part of digital mold technology, and it is the foundation of realizing the integration of mold design, manufacturing and inspection. TOYOTA, USA and other companies have realized the 3D design of the mold, and achieved good application results. Some practices abroad in the 3D design of moulds are worthy of our reference. In addition to the realization of integrated manufacturing, the three dimensional mold design is another advantage, which is convenient for interference inspection, and can carry on the motion interference analysis. It solves a problem in the two-dimensional design.

Tredje, the simulation CAE of stamping forming process is more prominent.

I de seneste år, with the rapid development of computer software and hardware, CAE simulation technology of stamping process plays an increasingly important role. In the developed countries such as the United States, Japan and Germany, CAE technology has become a necessary link in the mold design and manufacturing process. It is widely used to predict forming defects, optimize the stamping process and mold structure, improve the reliability of the die design and reduce the test time. Many automobile die enterprises in China have made remarkable progress in the application of CAE and achieved good results. The application of CAE technology can greatly save the cost of mold testing, shorten the development cycle of stamping mold, and has become an important means to ensure the quality of die. CAE technology is gradually transforming die design from experience design to scientific design.

JasonMould Industrial Company Limited, etableret i 2010, er en førende sprøjtestøbningsproducent i Kina. JasonMould er specialiseret i produktion af plastforme til husholdningsapparater, medicinsk udstyr, elektronisk udstyr, sikkerhedsudstyr samt overvågningssystem.

Virksomheden har overstået 15000 kvadratmeter fabrik. Med plastindsprøjtningsværktøjsafdelinger, der besidder forskelligt maskineri og ekspertise, JasonMould tilbyder værktøjer fra små og præcise mobiltelefondele til så store som bildele. Vores værktøjer eksporteres hovedsageligt til U.S.A., Europa, Japan og Storbritannien. JasonMoulds diversificeringsstrategi og fuld service har vundet komplimenter fra kunder over hele verden.

Vores mission er at give vores kunder højkvalitets støbeprodukter og -tjenester. Vi bestræber os på at overgå vores kunders forventninger til priser, kvalitet og levering til tiden. For at nå vores mission, JasonMould:

- Forpligter sig til løbende at forbedre medarbejdernes færdigheder og effektivitet,

- Giver vores medarbejdere et rent og sikkert arbejdsmiljø,

- Opgraderer maskinteknologi og supportudstyr gennem et strengt vedligeholdelsesprogram, og

- Vedligeholder kundernes værktøj til dets højeste ydeevne

For mere om tilpasset producent af plaststøbningsprodukter,besøg venligst https://www.jasonmolding.com/

Forespørgsel Kontakt:

Kontaktperson: James Yuan

Firmanavn: JasonMould Industrial Company Limited

Adresse: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong-provinsen, Kina

Telefon: 86-752-6682869

E-mail: [email protected]

Internet side: https://www.jasonmolding.com