Most of the defects of sprøjtestøbte dele are caused by the plasticization and injection stage of injection molded parts, men nogle gange urimeligt design. De påvirkende faktorer omfatter typen af injektionsindløb, antallet af skimmelsvampe, position og størrelse, udformningen af koldt/varmt løbesystem og selve produktets opbygning. Derfor, for at undgå produktfejl forårsaget af formdesign, vi skal analysere sprøjtestøbeformen under produktionen.

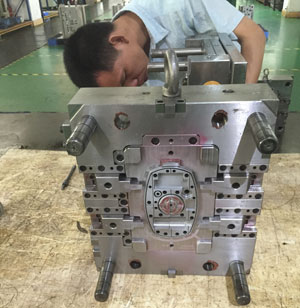

skimmelfremstilling

After getting the test results of the injection mold, the operator usually needs to re-evaluate the specific conditions of the mold to avoid unnecessary cost and time in the process of modification. I de fleste tilfælde, in order to compensate for the shortcomings in mold design, the operator may make incorrect settings without knowing, because the range of parameters required to produce qualified products is very small, once any deviation in the parameter settings may lead to the final product quality far beyond the allowable error. Range.

The purpose of injection mold test is to find out the optimized process parameters and die design. And not just to get a good sample. This is very important. Even if material, machine settings, or environmental factors change, it can ensure a stable and uninterrupted batch production environment.

JasonMouldIndustrialCompanyLimited, https://www.jasonmolding.com/ baseret i Guangdong-provinsen, Kina blev etableret i 2010. Virksomheden er en førende producent af sprøjtestøbning og har specialiseret sig i plaststøbning til brug i husholdningsapparater, elektronisk udstyr, medicinsk udstyr og sikkerhedsudstyr og overvågningssystemer.

Kontakt:

JasonMould Industrial Company Limited

Adresse: LongGang Village, LongXi Town, BoLuo County, HuiZhou City, GuangDong-provinsen, Kina

telefon: 86-752-6682869

E-mail: [email protected]

Internet side: https://www.jasonmolding.com/