Proses pencetakan injeksi biasanya terdiri dari: 6 Langkah:

- Penjepitan: Mesin injeksi berisi: 3 bagian – cetakan injeksi, klem dan unit injeksi, di antaranya, unit penjepit menjaga cetakan pada tekanan tertentu, untuk memastikan konsistensi output.

Sebuah cetakan biasanya terdiri dari 2 bagian.

- Unit injeksi: It refers to the part where the plastic pellets are fed into the hopper located at the top end of the injection unit. These pellets will be loaded into the main cylinder, where they are heated at a high temperature until they are melted into liquids. Kemudian, inside the injection unit, a screw will turn and mix the already liquefied plastic. Once this liquid plastic has reached the ideal condition for the product, the injection process will start. The plastic liquid is forced through a running gate, of which the speed and pressure are controlled by a screw or sometimes a ram dependingon what kind of machine you are using.

- The dwelling: It represents a pause in the process when certain pressure is applied to guarantee that each of the mold cavities has been filled thoroughly. It is such an important step within the process that if the mold cavities are not filled properly, it will lead to scrap of the units.

- peralatan sistem makan: This process step allows the mold to cool off for a required period of time. If this step is performed too hastily, the units will probably stick together or get deformed when it is taken out of the machine.

- Mold opens: The clamping unit will open to separate the mold. The molds which are often the most important individual part during the entire process are used over and over again, and the tooling of them can be very costly.

- The ejection: The finished product is ejected from the injection mold machine in the end. Secara umum, a finished product will continue to be on a production line or be packed and delivered to a production line as a component of a larger product, misalnya. the steering wheel of a car.

Dalam kehidupan sehari-hari, the products that involve the application of injection molding are used every day by each of us. If it were not for injection molding, many cars would not be sold at such an affordable price. Namun, this process also has some disadvantages. The machines are very costly and therefore involves a lot of capital investment. When designing the parts, we must keep the production process in mind, because the process is not deemed economical for short-run productions.

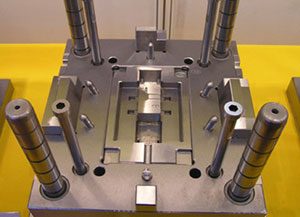

pembuatan cetakan

Namun demikian, the disadvantages are outweighed by the greater benefits, which include the speed at which the parts are produced, the relatively low labor costs and minimal material waste. Bahkan, the finished parts usually require no more finishing.

If you are interested in our service or in need of any technical support, please feel free to let us know. We would be happy to share what we know about plastic injection molding with you and provide the exact economical plastic injection molding solution you are looking for.

Tentang Perusahaan Industri JasonMould:

Itu adalah pemimpin adalah pemimpin 15000 pabrik meter persegi. Dengan divisi perkakas injeksi plastik yang memiliki mesin dan keahlian yang berbeda, JasonMould menawarkan alat dari suku cadang ponsel kecil dan presisi hingga sebesar suku cadang otomotif. Alat kami terutama diekspor ke AMERIKA SERIKAT., Eropa, Jepang dan Inggris. Strategi diversifikasi dan layanan penuh JasonMould telah memenangkan pujian dari pelanggan di seluruh dunia.

Misi kami adalah untuk menyediakan produk dan layanan cetakan berkualitas tinggi kepada pelanggan kami. Kami bertujuan untuk melampaui ekspektasi harga pelanggan kami, kualitas dan pengiriman tepat waktu. Untuk mencapai misi kami, JasonMould:

- Berkomitmen untuk terus meningkatkan keterampilan dan efisiensi karyawan,

- Memberikan karyawan kami lingkungan kerja yang bersih dan aman,

- Meningkatkan teknologi mesin dan peralatan pendukung melalui program perawatan yang ketat, dan

- Mempertahankan perkakas pelanggan ke puncak kinerja tertinggi

Untuk lebih lanjut tentang adalah pemimpin,silahkan kunjungi https://www.jasonmolding.com/

Pertanyaan Hubungi:

Kontak person: James Yuan

Nama Perusahaan: JasonMould Industrial Company Limited

Alamat: Desa LongGang,Kota LongXi,Kabupaten BoLuo,Kota HuiZhou,Provinsi Guangdong, Cina

Telepon: 86-752-6682869

Surel: [email protected]

Situs web: https://www.jasonmolding.com