Apa itu Die Casting?

Die casting adalah proses pengecoran logam yang ditandai dengan memaksa logam cair di bawah tekanan tinggi ke dalam rongga cetakan, terdiri dari dua die baja perkakas yang dikeraskan dan dikeraskan. Kebanyakan die casting terbuat dari logam non-ferrous, khusus seng, tembaga, aluminium, magnesium, memimpin, paduan berbasis timah dan timah. Tergantung pada jenis logam yang dilemparkan, a hot- or cold-chamber machine is used.

Two Types of Die Casting

There are two basic types of die casting machines: hot-chamber machines and cold-chamber machines. These are rated by how much clamping force they can apply. Typical ratings are between 400 dan 4,000 st (2,500 dan 25,400 kg).

Hot–Chamber Die Casting

The hot-chamber process is applicable only for zinc and other low melting point alloys that does not affect and erode metal pots cylinders and plungers.The molten metal for casting is placed in the holding furnace at the required temperature adjacent to(sometimes as part of the machine itself) the machine. The injection mechanism is placed within the holding furnace and most of its part is in constant touch with the molten metal. When pressure is transmitted by the injection piston, the metal is forced through the gooseneck into the die. On the return stroke, the metal is drawn towards the gooseneck for the next shot.This process ensures minimum contact between air and the metal to be injected. The tendency for entrainment of air in the metal during injection is also minimised.

Cold–Chamber Die Casting

The difference of this process with the hot-chamber process is that the injection system is not submerged in molten metal. Di sisi lain, metal gets transferred by ladle, manually or automatically, to the shot sleeve. The metal is pushed into the die by a hydraulically operated plunger. This process minimises the contact time between the injector components and the molten metal. Which extends the life of the components. However the entrainment of air into the metal generally associated with high-speed injection can cause gas porosity in the castings. In the cold chamber machine, injection pressures over 10,000 psi or 70,000 KPa is obtainable. Generally steel castings along with aluminium and copper based alloys are produced by this method.

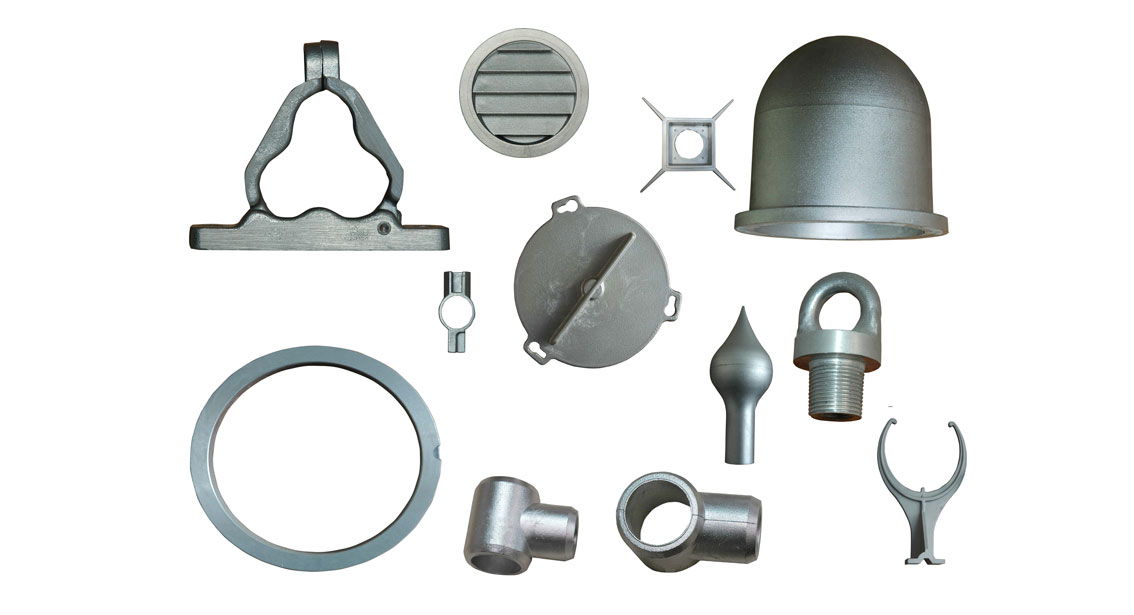

produk die-casting

Advantages of Die Casting

Excellent dimensional accuracy (dependent on casting material, but typically 0.1 mm for the first 2.5 cm (0.005 inch for the first inch) dan 0.02 mm for each additional centimeter (0.002 inch for each additional inch).

Smooth cast surfaces(Ra 1–2.5 micrometres or 0.04–0.10 thou rms).

Thinner walls can be cast as compared to sand and permanent mold casting (approximately 0.75 mm or 0.030 di).

Inserts can be cast-in (such as threaded inserts, heating elements, and high strength bearing surfaces).

Reduces or eliminates secondary machining operations.

Rapid production rates.

Casting tensile strength as high as 415 megapascals (60 ksi).

Casting of low fluidity metals.

JasonMould Industrial Company Limited adalah seorang profesional Perusahaan cetakan injeksi plastik Cinauntuk Pencetakan 3D Layanan Prototipe Cepat Rapid,layanan penggilingan CNC presisi dan kustom layanan permesinan CNC,cetakan injeksi plastik khusus atau perusahaan cetakan dengan pengembangan dan pembuatan cetakan dan cetakan. Kami menawarkan berbagai layanan proses die casting logam berkualitas tinggi Dengan pengalaman luas kami selama lebih dari delapan tahun di industri ini, kami memberikan solusi pengecoran terbaik yang dapat disesuaikan dengan kebutuhan Anda.

Kontak:

Orang: James Yuan

Perusahaan: JasonMould Industrial Company Limited

Menambahkan: Desa LongGang,Kota LongXi,Kabupaten BoLuo,Kota HuiZhou,Provinsi Guangdong, Cina.

Telp: 86-752-6682869

Surel: [email protected]

Situs:https://www.jasonmolding.com/plastic-injection-molding/