Most of the defects of produsen produk plastik cina are caused by the plasticization and injection stage of injection molded parts, tapi terkadang desainnya tidak masuk akal. Faktor-faktor yang mempengaruhi termasuk jenis inlet injeksi, jumlah rongga cetakan, posisi dan ukuran, desain sistem pelari dingin / panas dan struktur produk itu sendiri. Karena itu, untuk menghindari cacat produk yang disebabkan oleh desain cetakan, kita perlu menganalisis cetakan injeksi selama produksi.

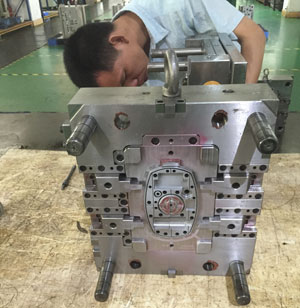

pembuatan cetakan

After getting the test results of the injection mold, the operator usually needs to re-evaluate the specific conditions of the mold to avoid unnecessary cost and time in the process of modification. Umumnya, in order to compensate for the shortcomings in mold design, the operator may make incorrect settings without knowing, because the range of parameters required to produce qualified products is very small, once any deviation in the parameter settings may lead to the final product quality far beyond the allowable error. Range.

The purpose of injection mold test is to find out the optimized process parameters and die design. And not just to get a good sample. This is very important. Even if material, machine settings, or environmental factors change, it can ensure a stable and uninterrupted batch production environment.

JasonMouldIndustrialCompanyLimited, https://www.jasonmolding.com/ based at GuangDong Province, China was established in 2010. The company is a leading manufacturer of injection moulding and specializes in plastic moulding for use in household appliances, peralatan elektronik, medical and safety equipment and monitoring systems.

Kontak:

JasonMould Industrial Company Limited

Alamat: Desa LongGang, Kota LongXi, Kabupaten BoLuo, Kota HuiZhou, Provinsi Guangdong, Cina

Telepon: 86-752-6682869

Surel: [email protected]

Situs web: https://www.jasonmolding.com/