İşte kalıbı parlatmanın iki ana amacı, biri plastik kalıbın parlaklığını ve güzelliğini arttırmaktır.. İkisi, kalıbın ölmesini kolaylaştırmak içindir.. Parlatma sürecinde, işlenmiş kalıp boşluğu yüzeyinin kaba taşlanması için ham petrol taşı kullanılır, alet işaretine taşlama, ve sonra ize ulaşmak için kaba yağ taşını elde etmek için ince yağ taşını kullanın, then the fine sand paper is used to grinding the surface of the fine oil stone, and then the polishing paste or the grinding paste is used. The surface of the mold cavity is finally polished and polished. Nihayet, the effect of bright mirror is achieved.

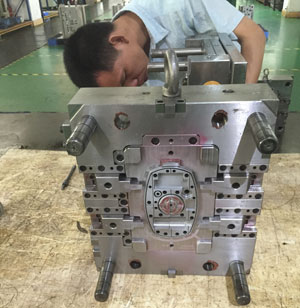

kalıp yapımı

Günlük yaşamda, our common plastic mold has six polishing methods:

- Mechanical polishing

Mechanical polishing is a smoothing method to get smooth surface by cutting, plastic deformation of material surface and removing the bump after being polished. Genel olarak, oil stone strip, wool wheel and sand paper are used for manual operation. Special parts, such as back body surface, can use auxiliary tools such as turntable, and the high quality of surface surface can be used for polishing and polishing. . The ultra precision polishing is a special abrasive tool, which is tightly pressed on the workpiece surface to rotate at high speed in the abrasive polishing fluid. Using this technology, the surface roughness of Ra0.008 M can be achieved, which is the highest among all kinds of polishing methods. This method is often used in optical lens moulds.

- Chemical polishing

Chemical polishing is to allow the material to protrude preferentially in the concave part of the surface in the chemical medium, so that the smooth surface can be obtained. The main advantage of this method is that it does not need complex equipment, can polish complex workpiece, and can polish many workpieces simultaneously, with high efficiency. The key problem of chemical polishing is the preparation of polishing solution. The surface roughness obtained by chemical polishing is generally 10 m.

- Electrolytic polishing

Electrolytic polishing is basically the same as chemical polishing, yani, by selectively dissolving the tiny protruding part of the material surface, making the surface smooth. Compared with chemical polishing, the effect of cathode reaction can be eliminated and the effect is better. The electrochemical polishing process is divided into two steps:

(1) the macro leveling dissolve product diffuses into the electrolyte, and the surface roughness of the material decreases, Ra>1 mu m.

(2) low light level anode polarization, surface brightness increased, Ra<1 m.

4, ultrasonic polishing

The workpiece is placed in the slurry suspension and placed in the ultrasonic field together, and the abrasive is grind and polish on the workpiece surface by the oscillating action of the ultrasonic wave. Ultrasonic machining has little macroscopic force and will not cause deformation of workpiece, but the manufacture and installation of tooling are more difficult. Ultrasonic machining can be combined with chemical or electrochemical methods. On the basis of solution corrosion and electrolysis, the ultrasonic vibration stirring solution is applied to dissolve the dissolving products on the surface of the workpiece, the corrosion or the electrolyte is uniform near the surface, and the cavitation effect of ultrasonic in the liquid can also inhibit the corrosion process and be beneficial to the light brightening of the surface.

- Fluid throwing

Fluid polishing is achieved by polishing the surface of the workpiece by means of high-speed flowing liquid and its abrasive particles. Common methods are abrasive jet machining, liquid jet machining, fluid dynamic grinding and so on. Hydrodynamic grinding is driven by hydraulics, so that liquid media carrying abrasive particles can flow across the workpiece surface at high speed. The medium is mainly made of special compound (polymer like substance) with good flowability under low pressure and mixed with abrasives. Silicon carbide powder can be used for abrasive.

- Magnetic abrasive polishing

Magnetic abrasive finishing is to use magnetic abrasive to form abrasive brush under the action of magnetic field and to grind the workpiece. This method has high processing efficiency, iyi kalite, easy control of processing conditions and good working conditions. With suitable abrasives, the surface roughness can reach Ra0.1 m.

JasonMould Sanayi Limited Şirketi, kuruldu 2010, Çin'in önde gelen enjeksiyon kalıp üreticisidir. JasonMould, ev aletleri için plastik kalıp üretiminde uzmanlaşmıştır, Medikal ekipmanlar, elektronik ekipmanlar, güvenlik ekipmanlarının yanı sıra izleme sistemi.

şirket bitti 15000 metrekare fabrika. Farklı makine ve uzmanlıklara sahip plastik enjeksiyon kalıplama bölümleri ile, JasonMould, küçük ve hassas cep telefonu parçalarından otomotiv parçaları kadar büyük parçalara kadar araçlar sunar. Aletlerimiz ağırlıklı olarak ABD'ye ihraç edilmektedir., Avrupa, Japonya ve İngiltere. JasonMould'un çeşitlendirme stratejisi ve tam hizmeti, dünyanın her yerindeki müşterilerden övgü aldı.

Misyonumuz, müşterilerimize yüksek kaliteli kalıplama ürünleri ve hizmetleri sunmaktır.. Müşterilerimizin fiyatlandırma beklentilerini aşmayı hedefliyoruz, kaliteli ve zamanında teslimat. Misyonumuza ulaşmak için, JasonKalıp:

- Çalışan becerilerini ve verimliliğini sürekli iyileştirmeyi taahhüt eder,

- Çalışanlarımıza temiz ve güvenli bir çalışma ortamı sağlar,

- Sıkı bir bakım programı aracılığıyla makine teknolojisini ve destek ekipmanını yükseltir, ve

- Müşterilerin takımlarını en yüksek performans zirvesinde tutar

Özel plastik kalıp ürünleri üreticisi hakkında daha fazla bilgi için,lütfen ziyaret edin https://www.jasonmolding.com/

Soruşturma İletişim:

İlgili kişi: James Yuan

Şirket Adı: JasonMould Sanayi Limited Şirketi

Adres: Uzun Çete Köyü,LongXi Kasabası,BoLuo İlçe,HuiZhou Şehri,Guangdong Eyaleti, Çin

Telefon: 86-752-6682869

E-posta: [email protected]

İnternet sitesi: https://www.jasonmolding.com