ecco due scopi principali per lucidare lo stampo, uno è aumentare la luminosità e la bellezza dello stampo in plastica. I due sono per rendere il dado facile da estinguere. In fase di lucidatura, la pietra petrolifera grezza viene utilizzata per la molatura grossolana della superficie della cavità dello stampo lavorato, affilatura fino al segno dell'utensile, e poi usando la pietra a olio fine per ottenere la pietra a olio grossolana per raggiungere la traccia, then the fine sand paper is used to grinding the surface of the fine oil stone, and then the polishing paste or the grinding paste is used. The surface of the mold cavity is finally polished and polished. Infine, the effect of bright mirror is achieved.

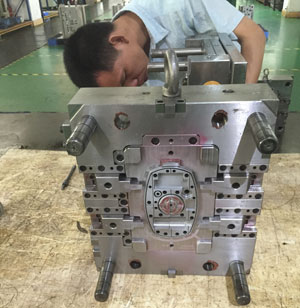

fabbricazione di stampi

Nella vita quotidiana, our common plastic mold has six polishing methods:

- Mechanical polishing

Mechanical polishing is a smoothing method to get smooth surface by cutting, plastic deformation of material surface and removing the bump after being polished. Generalmente, oil stone strip, wool wheel and sand paper are used for manual operation. Special parts, such as back body surface, can use auxiliary tools such as turntable, and the high quality of surface surface can be used for polishing and polishing. . The ultra precision polishing is a special abrasive tool, which is tightly pressed on the workpiece surface to rotate at high speed in the abrasive polishing fluid. Using this technology, the surface roughness of Ra0.008 M can be achieved, which is the highest among all kinds of polishing methods. This method is often used in optical lens moulds.

- Chemical polishing

Chemical polishing is to allow the material to protrude preferentially in the concave part of the surface in the chemical medium, so that the smooth surface can be obtained. The main advantage of this method is that it does not need complex equipment, can polish complex workpiece, and can polish many workpieces simultaneously, with high efficiency. The key problem of chemical polishing is the preparation of polishing solution. The surface roughness obtained by chemical polishing is generally 10 m.

- Electrolytic polishing

Electrolytic polishing is basically the same as chemical polishing, questo è, by selectively dissolving the tiny protruding part of the material surface, making the surface smooth. Compared with chemical polishing, the effect of cathode reaction can be eliminated and the effect is better. The electrochemical polishing process is divided into two steps:

(1) the macro leveling dissolve product diffuses into the electrolyte, and the surface roughness of the material decreases, Ra>1 mu m.

(2) low light level anode polarization, surface brightness increased, Ra<1 m.

4, ultrasonic polishing

The workpiece is placed in the slurry suspension and placed in the ultrasonic field together, and the abrasive is grind and polish on the workpiece surface by the oscillating action of the ultrasonic wave. Ultrasonic machining has little macroscopic force and will not cause deformation of workpiece, but the manufacture and installation of tooling are more difficult. Ultrasonic machining can be combined with chemical or electrochemical methods. On the basis of solution corrosion and electrolysis, the ultrasonic vibration stirring solution is applied to dissolve the dissolving products on the surface of the workpiece, the corrosion or the electrolyte is uniform near the surface, and the cavitation effect of ultrasonic in the liquid can also inhibit the corrosion process and be beneficial to the light brightening of the surface.

- Fluid throwing

Fluid polishing is achieved by polishing the surface of the workpiece by means of high-speed flowing liquid and its abrasive particles. Common methods are abrasive jet machining, liquid jet machining, fluid dynamic grinding and so on. Hydrodynamic grinding is driven by hydraulics, so that liquid media carrying abrasive particles can flow across the workpiece surface at high speed. The medium is mainly made of special compound (polymer like substance) with good flowability under low pressure and mixed with abrasives. Silicon carbide powder can be used for abrasive.

- Magnetic abrasive polishing

Magnetic abrasive finishing is to use magnetic abrasive to form abrasive brush under the action of magnetic field and to grind the workpiece. This method has high processing efficiency, buona qualità, easy control of processing conditions and good working conditions. With suitable abrasives, the surface roughness can reach Ra0.1 m.

JasonMuld Industrial Company Limited, stabilito in 2010, è un produttore leader di stampaggio a iniezione in Cina. JasonMould è specializzato nella produzione di stampi in plastica per elettrodomestici, attrezzature mediche, apparecchiature elettroniche, dispositivi di sicurezza e sistema di monitoraggio monitoring.

L'azienda ha finito 15000 fabbrica di metri quadrati. Con divisioni di utensili per iniezione plastica che possiedono diversi macchinari e competenze, JasonMould offre strumenti da parti di telefoni cellulari piccole e precise a parti grandi come automobili. I nostri strumenti vengono esportati principalmente negli Stati Uniti., Europa, Giappone e Regno Unito. La strategia di diversificazione di JasonMould e il servizio completo hanno ricevuto complimenti dai clienti di tutto il mondo.

La nostra missione è fornire ai nostri clienti prodotti e servizi di stampaggio di alta qualità. Miriamo a superare le aspettative di prezzo dei nostri clienti, qualità e puntualità nelle consegne. Per raggiungere la nostra missione, JasonMold:

- Si impegna a migliorare continuamente le capacità e l'efficienza dei dipendenti,

- Fornisce ai nostri dipendenti un ambiente di lavoro pulito e sicuro,

- Aggiorna la tecnologia della macchina e le attrezzature di supporto attraverso un rigoroso programma di manutenzione, e

- Mantiene gli utensili dei clienti al massimo delle prestazioni

Per ulteriori informazioni sul produttore personalizzato di prodotti per lo stampaggio della plastica,per favore visita https://www.jasonmolding.com/

Richiesta Contatto:

Referente: James Yuan

Nome della ditta: JasonMuld Industrial Company Limited

Indirizzo: Villaggio LongGang,Città di LongXi,Contea di BoLuo,HuiZhou Cityhou,Provincia di Guangdong, Cina

Telefono: 86-752-6682869

E-mail: [email protected]

Sito web: https://www.jasonmolding.com