- Wanneer de spuitgietmatrijs met enkelvoudig scheidingsoppervlak wordt geopend:, de bewegende matrijs en de vaste matrijs zijn gescheiden, en de plastic onderdelen worden eruit gehaald, die de enkele scheidingsoppervlakvorm en de dubbele plaatvorm wordt genoemd;. It is the simplest and most basic form of injection mould. It can be designed as a single cavity injection mould or a multi-cavity injection mould according to the need. It is the most widely used injection mold.

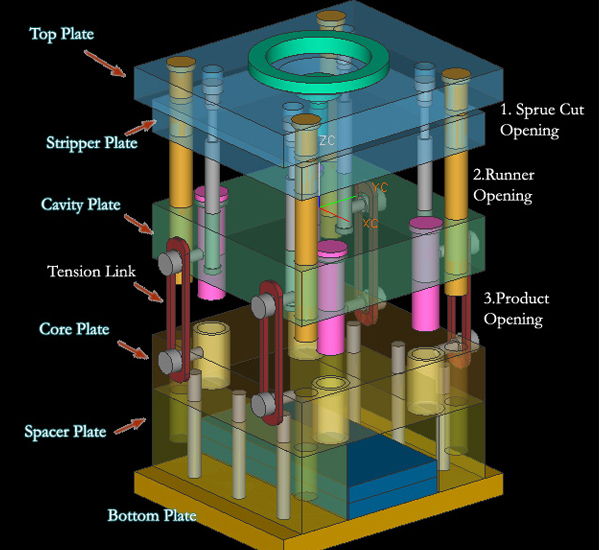

- The double parting surface injection mould has two parting surfaces. Compared with the single parting surface injection mould, the double parting surface injection mould adds a movable middle plate (also called movable gate board) in the fixed part of the mould. It has a gate, hardloper, and other parts and components needed for a fixed mold, so it is also called a three-plate injection mould (bewegende sjabloon, middle plate, fixed template). It is often used for injection molds with single or multiple cavities that point gate feed, when opening a mold, The intermediate plate is separated from the fixed template at a fixed distance on the guide column of the die to remove the castable system between the two templates. The injection mould with double parting surface is complex in structure, high in manufacturing cost and difficult in parts processing, so it is not generally used in the molding of large or super large plastic products.

- Injection molds with lateral parting and core-pulling mechanism. When plastic parts have side holes or side recesses, lateral moving cores or sliders should be used. After injection molding, the dynamic die moves a distance down first, then the inclined section of the bending pin fixed on the fixed template forces the slider to move outwards. Tegelijkertijd, the push rod of the demoulding mechanism pushes the push plate to make the plastic part take off from the core.

- Because of some special structure of plastic parts, injection molds with movable forming parts require movable molding parts, such as movable punch, movable concave die, movable insert, movable thread core or ring, enzovoort. During demoulding, you can move out of the mold together with the plastic parts, and then separate from the plastic parts.

- For plastic parts with screw threads, the injection mould can be automatically unthreaded by setting a thread core or ring that can be rotated on the mould, using the opening action or the rotating mechanism of the injection molding machine, or setting up a special transmission device. Drive screw thread core or thread ring rotation, so as to remove plastic parts.

- The injection mould without runner is the method of adiabatic heating of the runner, which keeps the plastic melt from the one cavity of the nozzle of the injection molding machine, and makes the mold take out the plastic parts without the pouring system solidification. The former is called adiabatic injection mold, the latter is called hot runner injection mold.

- The right angle injection mould is only suitable for the angular injection molding machine, which is different from other injection molds in that the feeding direction of the mould is perpendicular to the opening and closing direction of the mould. His main channel is set on both sides of the moving, fixed parting surface, and its cross section is usually the same, which is different from the mold used in other injection molding machines, the end of the main channel. In order to prevent the abrasion and deformation of the nozzle and the main inlet of the injection molding machine, replaceable runner inserts can be set up.

- In most injection molds, the demoulding device is installed on the side of the moving mold, which is advantageous to the work of ejection device in the opening and closing system of the injection molding machine. In actual production, because some plastic parts are limited by the shape, it is better to leave the plastic parts on the one side of the fixed mold, so that the plastic parts can be removed from the mold, so the demoulding mechanism must be set on the side of the fixed mold.

Jasonmould is een fabrikant van plastic mallen- spuitgietmatrijs:, spuitgietmatrijzen, kunststof blaasvormen, rotatiegieten, medisch kunststof spuitgieten, twee schots kunststof spuitgieten, invoegen lijstwerk, overmolding, metalen spuitgieten, micro-spuitgieten, poeder spuitgieten, keramisch spuitgieten, vloeibare spuitgieten, husky spuitgieten, huishoudelijke schimmel, gietvorm, matrijs gereedschap:, aangepaste mallen, Chinese mallen:, tooling voor snelle prototyping, kunststof prototyping gereedschap, ponsmachine tooling, sterven en tooling voor mobiele/mobiele telefoon onderdelen, auto-onderdelen, stofzuigers, oplaadbare gereedschappen, telefoons, kopieerapparaten, computers, multimedia speakers, en vele andere elektronische producten en huishoudelijke apparaten. En ook een fabrikant van plastic producten- plastic onderdelen, plastic watertank, plastic ballen, plastic containers, plastic gesp, plastic anker, plastic hanger, Plastic lepel, plastic pijp montage:, plastic tuimelen, plastic servies, plastic bekers, plastic flessen, plastic dienblad, plastic cosmetische container, plastic verpakking, plastic voedselcontainer, plastic stoelen, plastic doppen, plastic dop sluiting, plastic buizen, kunststof waterleidingen, plastic knoppen, plastic buizen, plastic gebruiksdozen, plastic rekken enzovoort;.

Jasonmould is een fabrikant van plastic mallen- spuitgietmatrijs:, spuitgietmatrijzen, kunststof blaasvormen, rotatiegieten, medisch kunststof spuitgieten, twee schots kunststof spuitgieten, invoegen lijstwerk, overmolding, metalen spuitgieten, micro-spuitgieten, poeder spuitgieten, keramisch spuitgieten, vloeibare spuitgieten, husky spuitgieten, huishoudelijke schimmel, gietvorm, matrijs gereedschap:, aangepaste mallen, Chinese mallen:, tooling voor snelle prototyping, kunststof prototyping gereedschap, ponsmachine tooling, sterven en tooling voor mobiele/mobiele telefoon onderdelen, auto-onderdelen, stofzuigers, oplaadbare gereedschappen, telefoons, kopieerapparaten, computers, multimedia speakers, en vele andere elektronische producten en huishoudelijke apparaten. En ook een fabrikant van plastic producten- plastic onderdelen, plastic watertank, plastic ballen, plastic containers, plastic gesp, plastic anker, plastic hanger, Plastic lepel, plastic pijp montage:, plastic tuimelen, plastic servies, plastic bekers, plastic flessen, plastic dienblad, plastic cosmetische container, plastic verpakking, plastic voedselcontainer, plastic stoelen, plastic doppen, plastic dop sluiting, plastic buizen, kunststof waterleidingen, plastic knoppen, plastic buizen, plastic gebruiksdozen, plastic rekken enzovoort;.Contact:

Contactpersoon: James Yuan

Bedrijfsnaam: JasonMould Industrial Company Limited

Adres: LongGang Village,LongXi Town,BoLuo County,HuiZhou-stad,Provincie GuangDong, China

Telefoon: 86-752-6682869

E-mail: [email protected]

Website: https://www.jasonmolding.com

18

april