Zgodnie z różnymi metodami formowania, możemy podzielić różne rodzaje form do przetwórstwa tworzyw sztucznych odpowiadające różnym wymaganiom procesowym, głównie w tym forma wtryskowa, forma do wytłaczania, plastikowa forma ssąca, forma z polistyrenu wysokopiennego i tak dalej.

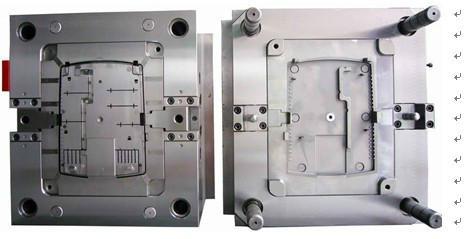

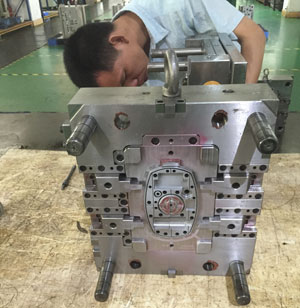

1.Forma wtryskowa z tworzywa sztucznego

Jest to głównie rodzaj formy formierskiej, która jest szeroko stosowana w produkcji części termoplastycznych. Odpowiednim sprzętem do przetwarzania form wtryskowych z tworzyw sztucznych jest wtryskarka do tworzyw sztucznych. The plastics are first heated and melted in the bottom heating drum of the injection machine.Then the injection machine screw or plunger push through the injection machine nozzles and mold gating system into the mold cavity plastic cooling hardening molding mold to get products.The structure is usually composed of molding parts, gating systems, guide parts, push mechanism, i czy kolor jest jasny i półprzezroczysty, i czy kolor jest jasny i półprzezroczysty, supporting parts and so on.The main materials are carbon structural steel, carbon tool steel, alloy tool steel, high speed steel and so on.The injection molding process is usually only suitable for the production of thermoplastics products. The plastic products produced by the injection molding process are very extensive, ranging from daily necessities to all kinds of complicated machinery and electrical appliances.The parts of vehicle are molded by injection mould, which is the most widely used processing method in plastic production.

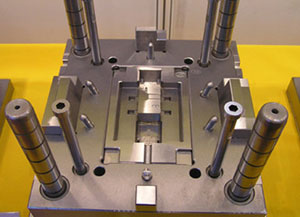

2.Plastic pressure-plastic mould

Including compression molding and injection molding two types of structural die.They are mainly used to form thermosetting plastics, the corresponding equipment is a pressure molding machine.Compression molding method according to the plastic characteristics, the mould is heated to the molding temperature (ogólnie 103 °-108 °), then the measured compression and plastic powder is put into the mold cavity and feeding chamber to close the mold, and the plastic shows a softening viscous flow under the action of high heat and high pressure.After a certain period of time, solidify the shape of the desired product.Different from the compression molding, there is a separate feeding chamber, the mold is closed before forming, the preheating of the plastic in the feeding chamber is viscous, and the plastic is extruded into the die cavity under the action of pressure and hardened.Compression moulds are also used to form some special thermoplastic such as hard to melt thermoplastic (such as polyfluoroethylene) blank (cold pressing molding, high optical properties of resin lens, slightly foaming nitrate cellulose steering wheel and so on.The molding die is mainly made up of cavity, feeding cavity, mechanizm prowadzący, pushing parts, heating system and so on.Injection die is widely used in packaging electrical components.The material used in the manufacture of the pressure-plastic mould is basically the same as the injection mould.

3.Plastic extrusion mould

A kind of mould used to produce continuous plastic products, also called extrusion head, is widely used in the processing of pipe, bar, single filament, sheet, film, wire and cable coating, profile, etc.The corresponding production equipment is the plastic extruder. The principle is that the solid plastic is melted and plasticized under the condition of heating and extruder’s screw rotation and pressure, and the continuous plastic products with the same cross section and die shape are made through the die with a specific shape.The main manufacturing materials are carbon structural steel, alloy tools, and some extrusion dies will insert diamond and other wear-resistant materials on the parts that need wear resistance.Extrusion process is usually only suitable for the production of thermoplastic products, and its structure is obviously different from that of injection molds and compression molds.

4.Plastic blow mould

It is a mold used to form hollow products of plastic containers (takie jak butelki z napojami, daily chemicals and other packaging containers). According to the principle of technology, the main forms of blow molding are extrusion blow molding, injection blow molding hollow molding.Injection extended blow molding hollow molding (powszechnie znany jako “injection-pull blowing”), multi-layer blow-molding hollow molding, sheet blow-molding hollow molding, etc.The equipment corresponding to blow molding of hollow products is usually called plastic blow molding machine, and blow molding is only suitable for the production of thermoplastic products.Blow mold structure is relatively simple, the materials used to make more carbon.

5.Plastic suction mould

It is a kind of mould which uses plastic sheet or sheet as raw material to form some simple plastic products. The principle is that the plastic plate fixed on the die or punch is made by using vacuum blooming method or compressed air forming method.In the case of heating and softening deformation and sticking to the mold cavity to obtain the necessary molding products, mainly used in some daily necessities, jedzenie, toys packaging products production.Because of the low pressure during molding, the mould materials are made of cast aluminum or non-metallic materials, and the structure is relatively simple.

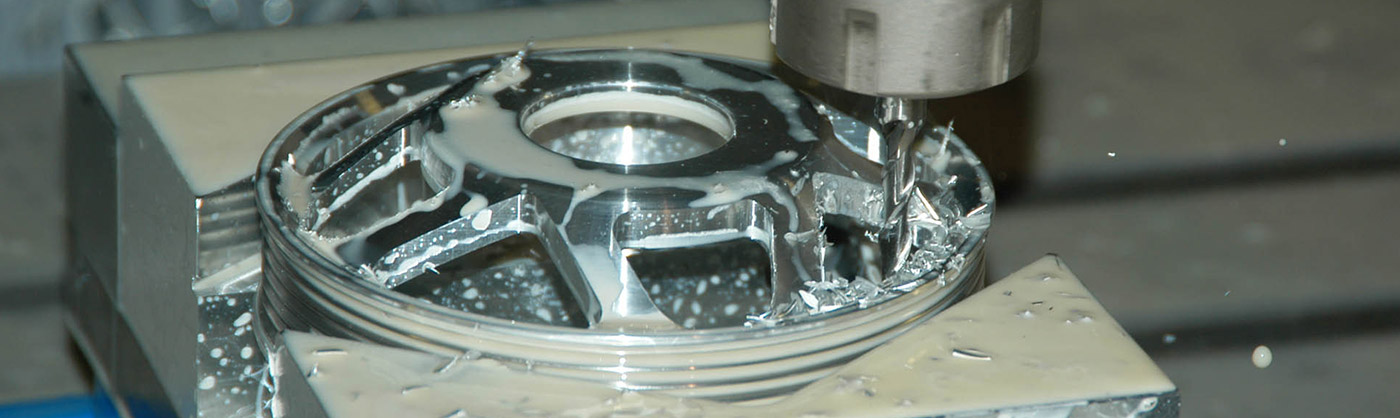

tworzenie form

6.Plastic high foaming polystyrene mould

Is the application of expandable polystyrene (bead material consisting of polystyrene and foaming agent) a mold foam packing material to forming all kinds of raw materials required for the shape. The principle is to die in the internal energy of steam into polystyrene molding, including simple manual type foam mold molds and hydraulic straight through processing of two types of main for the production of industrial packaging products. Die manufacturing such materials are cast aluminum, Stal nierdzewna, bronze and so on.

O JasonMould Industrial Company Limited

Jasonmould jest producentem form plastikowych- forma wtryskowa, formy odlewnicze, formowanie z rozdmuchiwaniem z tworzywa sztucznego,, formowanie rotacyjne, medyczny formowanie wtryskowe tworzyw sztucznych, dwa strzały formowanie wtryskowe tworzyw sztucznych, wkładka do formowania, obtryskiwanie, formowanie wtryskowe metalu, mikroformowanie wtryskowe, formowanie wtryskowe proszków, ceramiczne formowanie wtryskowe, płynne formowanie wtryskowe, husky formowanie wtryskowe, pleśń domowa, odlewanie formy, narzędzie do formowania matrycy, niestandardowe formy, formy z porcelany, oprzyrządowanie do szybkiego prototypowania, oprzyrządowanie do prototypowania tworzyw sztucznych, oprzyrządowanie do dziurkowania, matryca i oprzyrządowanie do części do telefonów komórkowych / telefonów komórkowych cell, części samochodowe, odkurzacze, narzędzia ładowalne, telefony, kopiarki, komputery, głośniki multimedialne, oraz wiele innych produktów elektronicznych i AGD. A także producent wyrobów z tworzyw sztucznych- plastikowe części, plastikowy zbiornik na wodę, plastikowe kulki, plastikowe pojemniki, plastikowa klamra, plastikowa kotwica, plastikowy wieszak, plastikowa łyżka, plastikowa złączka do rur,, plastikowe upadki, plastikowe zastawy stołowe, plastikowe kubki, plastikowe butelki, Taca z tworzywa sztucznego, plastikowy pojemnik kosmetyczny, plastikowa obudowa, plastikowy pojemnik na żywność, plastikowe krzesła, plastikowe nasadki, plastikowe zamknięcie nasadki, plastikowe rurki, plastikowe rury wodne, plastikowe gałki, plastikowe rurki, plastikowe pudełka na narzędzia, plastikowe stojaki i tak dalej.

Kontakt:

Osoba: James Yuan

Firma: JasonMould Industrial Company Limited

Dodaj:LongGangVillage,LongXiMiasto,Okręg BoLuo,HuiZhouCity,Prowincja Guangdong, Chiny

Tel: 86-752-6682869

E-mail: [email protected]

Teren:https://www.jasonmolding.com/custom-injection-molding/