Im 1868, Heyat developed a Plastik material called celluloid. Faserorientierung in jedem Komplex 1851. Faserorientierung in jedem Komplex. Faserorientierung in jedem Komplex, In 1872, Faserorientierung in jedem Komplex. This machine is relatively simple than that used in the 20 th century. It basically works like a giant hypodermic syringe needle. The giant needle (diffuser) injects plastic into the mold through a heated cylinder.

In the 1940s World War II resulted in a huge demand for cheap, mass-produced products.

Im 1946, American inventor James Watson Hendry built the first injection molding machine, which made it more accurate to control the speed and quality of the injection produced. The machine also allows color or recycled plastics to be thoroughly mixed into raw materials before injection. Im 1951, the United States developed the first screw injector, which was not patented, and the device is still in use.

In the 1970s, Hendry then developed the first gas-assisted injection molding process, allowing complex, hollow products to cool quickly. This greatly improves design flexibility as well as strength and end-point components, while reducing production time, Kosten, weight and waste.

Spritzguss, also called injection molding, is a method of injection and molding. The advantages of the injection molding method are fast production speed, hohe Effizienz, automation of operation, variety of designs, simple to complex shapes, size from large to small, precise size of products, and easy updating of products. Can form complex shape parts, injection molding suitable for mass production and shape complex products and other molding processing fields.

At a certain temperature, a completely fused plastic material is stirred by a screw, and the molding method is obtained after cooling and curing with high pressure. This method is suitable for mass production of complex parts. It is one of the important processing methods.

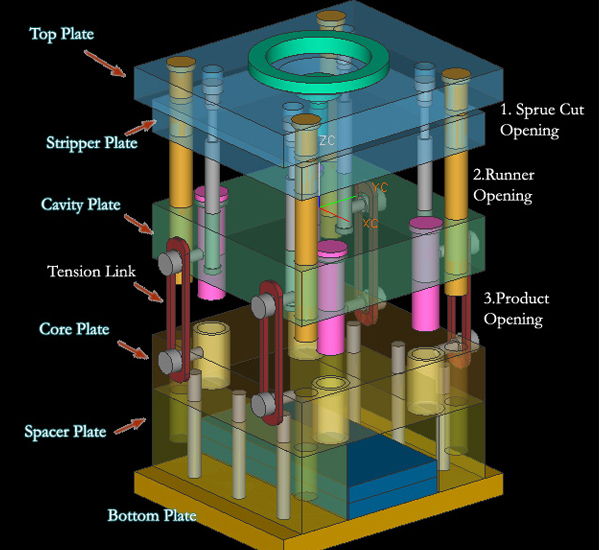

The injection molding process can be roughly divided into the following six stages: Moulding, gelling, keeping pressure, Kühlung, opening mould, product removal

The above process is repeated, can be batch periodic production of products. The molding of thermosetting plastics and rubber also includes the same process, but the temperature of the cylinder is lower than that of the thermoplastic, but the injection pressure is higher, the mould is heated, the material injection needs to be cured or vulcanized in the mould, and then the film is removed while the heat is hot.

Heutzutage, the trend of processing technology is developing in the direction of high and new technology. These technologies include micro injection molding, high filling compound injection molding, water assisted injection molding, mixed use of various special injection molding processes, foam injection molding, mold technology, Simulation techniques, usw.

Über JasonMould Industriegesellschaft mit beschränkter Haftung

Jasonmould ist ein Hersteller von Kunststoffformen- Spritzgussform, Druckgussformen, Kunststoffblasformen plastic, Rotationsformen, medizinischer Kunststoffspritzguss, Zwei-Schuss-Kunststoff-Spritzguss, Umspritzen, Umspritzen, Metallspritzguss, Mikrospritzguss, Pulverspritzguss, Keramikspritzguss, Flüssigspritzguss, Husky-Spritzguss, Haushaltsform, Gießform, Formwerkzeug, benutzerdefinierte Formen mold, Porzellanformen, Rapid-Prototyping-Werkzeuge, Kunststoff-Prototyping-Werkzeuge, Stanzpresswerkzeuge, Matrize und Werkzeuge für Handy-/Handyteile, Autoteile, Staubsauger, wiederaufladbare Werkzeuge, Telefone, Kopierer, Computers, Multimedia-Lautsprecher, und viele andere elektronische Produkte und Haushaltsgeräte. Und auch ein Hersteller von Kunststoffprodukten- Kunststoffteile, Wassertank aus Kunststoff, Plastikkugeln, Kunststoffbehälter, Plastikschnalle, Kunststoffanker, Kleiderbügel aus Kunststoff, Plastiklöffel, Rohrverschraubung aus Kunststoff, Plastiktrommel, Plastikgeschirr plastic, Plastiktassen, Plastikflaschen, Plastikschale, Kosmetikbehälter aus Kunststoff, Plastikbehälter, Lebensmittelbehälter aus Plastik, Plastikstühle, Plastikkappen, Verschluss aus Kunststoff, Kunststoffrohre, Wasserrohre aus Kunststoff, Kunststoffknöpfe, Kunststoffschlauch, Gebrauchskartons aus Kunststoff, Plastikregale und so weiter.

Kontakt:

Gesprächspartner: James Yuan

Name der Firma: JasonMould Industrial Company Limited

Adresse: LongGang-Dorf,LongXi-Stadt,Bezirk BoLuo,Stadt HuiZhou,Provinz Guangdong, China

Telefon: 86-752-6682869

Email: [email protected]

Webseite: https://www.jasonmolding.com