precisie en kwetsbaarheid van schimmel 6 precisie en kwetsbaarheid van schimmel:

- precisie en kwetsbaarheid van schimmel: precisie en kwetsbaarheid van schimmel 3 precisie en kwetsbaarheid van schimmel, precisie en kwetsbaarheid van schimmel, precisie en kwetsbaarheid van schimmel, precisie en kwetsbaarheid van schimmel, so as to ensure the consistency of the outputs.

A mold is usually made up of 2 onderdelen.

- The injection unit: It refers to the part where the plastic pellets are fed into the hopper located at the top end of the injection unit. These pellets will be loaded into the main cylinder, where they are heated at a high temperature until they are melted into liquids. Dan, inside the injection unit, a screw will turn and mix the already liquefied plastic. Once this liquid plastic has reached the ideal condition for the product, the injection process will start. The plastic liquid is forced through a running gate, of which the speed and pressure are controlled by a screw or sometimes a ram dependingon what kind of machine you are using.

- The dwelling: It represents a pause in the process when certain pressure is applied to guarantee that each of the mold cavities has been filled thoroughly. It is such an important step within the process that if the mold cavities are not filled properly, it will lead to scrap of the units.

- de koeling: This process step allows the mold to cool off for a required period of time. If this step is performed too hastily, the units will probably stick together or get deformed when it is taken out of the machine.

- Mold opens: The clamping unit will open to separate the mold. The molds which are often the most important individual part during the entire process are used over and over again, and the tooling of them can be very costly.

- The ejection: The finished product is ejected from the injection mold machine in the end. In het algemeen, a finished product will continue to be on a production line or be packed and delivered to a production line as a component of a larger product, bijv. the steering wheel of a car.

In het dagelijkse leven, the products that involve the application of injection molding are used every day by each of us. If it were not for injection molding, many cars would not be sold at such an affordable price. Echter, this process also has some disadvantages. The machines are very costly and therefore involves a lot of capital investment. When designing the parts, we must keep the production process in mind, because the process is not deemed economical for short-run productions.

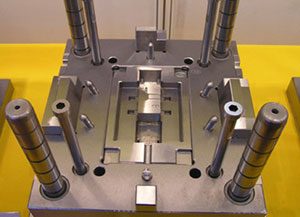

mallen maken

Nevertheless, the disadvantages are outweighed by the greater benefits, which include the speed at which the parts are produced, the relatively low labor costs and minimal material waste. Ook al, the finished parts usually require no more finishing.

If you are interested in our service or in need of any technical support, please feel free to let us know. We would be happy to share what we know about plastic injection molding with you and provide the exact economical plastic injection molding solution you are looking for.

About JasonMould Industrial Company:

De bedrijf heeft voorbij 15000 vierkante meter fabriek. Met divisies voor kunststofinjectiegereedschappen met verschillende machines en expertise, JasonMould biedt gereedschappen van kleine en nauwkeurige onderdelen voor mobiele telefoons tot zo groot als auto-onderdelen. Onze gereedschappen worden voornamelijk geëxporteerd naar de V.S., Europa, Japan en het VK. De diversificatiestrategie en volledige service van JasonMould hebben complimenten gekregen van klanten over de hele wereld.

Onze missie is om onze klanten hoogwaardige vormproducten en -diensten te bieden. We streven ernaar de prijsverwachtingen van onze klanten te overtreffen, kwaliteit en stipte levering. Om onze missie te bereiken, JasonMould:

- Zet zich in om de vaardigheden en efficiëntie van medewerkers voortdurend te verbeteren,

- Biedt onze medewerkers een schone en veilige werkomgeving,

- Upgradet machinetechnologie en ondersteunende apparatuur via een strikt onderhoudsprogramma, en

- Handhaaft de tooling van klanten op het hoogste prestatieniveau

Voor meer over China spuitgieten kosten:,bezoek alstublieft https://www.jasonmolding.com/

Aanvraag Contact::

Contactpersoon: James Yuan

Bedrijfsnaam: JasonMould Industrial Company Limited

Adres: LongGang Village,LongXi Town,BoLuo County,HuiZhou-stad,Provincie GuangDong, China

Telefoon: 86-752-6682869

E-mail: [email protected]

Website: https://www.jasonmolding.com