Failure often occurs in the use of mallen, Vonkvrije hamer of, Vonkvrije hamer of. Vonkvrije hamer of:

- Vonkvrije hamer of

Vonkvrije hamer of; of het warmtebehandelingsproces is niet correct, niet om de beste sterkte en taaiheid van staal te bereiken; oneigenlijk gebruik van de matrijs veroorzaakt lokale overbelasting; for hot-working mold softening at high temperature will also lead to mold thermoplastic deformation failure. Deformation failure can lead to deformation of the mold and ultimately affect the quality of the forging.

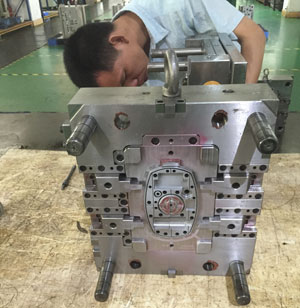

mallen maken

- 2.Moldswear failure

The basic reason for the failure of the mold is the friction between the mold and the billet. But the specific form of wear and the wear process are related to many factors, such as the pressure, temperatuur-, deformation speed and lubrication condition of the mold in the working process. For hot working mold, the wear resistance decreases due to the softening of cavity surface by high temperature, and the oxide scale itself plays an abrasive role, which determines that the wear process is more complex. The wear failure of the mold mainly results in the wear of the forging mold and the accuracy of the forging.

- Fatigue failure of molds

The ultimate cause of fatigue failure is the stress concentration and cyclic load. Although the load on the mold is sometimes significantly lower than its yield strength, due to local stress concentration, under low load, microcracks still form at the stress concentration. The dies are usually in high strength and low plasticity. When the micro-cracks are formed, the micro-cracks are easy to propagate and ultimately lead to fatigue fracture under the cyclic loading of the dies.

- Cold and hot fatigue failure of molds

For the hot working mold, the surface temperature of the mold often rises to 600 ~ 900 C because of the interaction with the hot blank. In order not to reduce the strength of the mold, the mold must be sprayed with a coolant to cool it down. This cycle is a process of rapid cooling and rapid heating on the surface of the mold, and a considerable cyclic thermal stress is accumulated on the surface of the mold. The stress is finally released in the form of cold and hot fatigue, forming cold and hot fatigue cracks. As for high temperature oxidation, corrosion of coolant and friction between mould and high temperature billet, the process of cold and hot fatigue is accelerated.

- Failure under the influence of comprehensive factors

The working conditions of the mold are intricate, so the occurrence of damage events occur from time to time. Once the damage is caused, they may promote each other, and ultimately accelerate the failure of the mold.

JasonMould Industrial Company Limited, gevestigd in 2010, is een toonaangevende fabrikant van spuitgieten in China;. JasonMould is gespecialiseerd in de productie van plastic matrijzen voor huishoudelijke apparaten, medische apparatuur, elektronische apparatuur, veiligheidsuitrusting evenals controlesysteem;.

Het bedrijf is voorbij 15000 vierkante meter fabriek. Met divisies voor kunststofinjectiegereedschappen met verschillende machines en expertise, JasonMould biedt gereedschappen van kleine en nauwkeurige onderdelen voor mobiele telefoons tot zo groot als auto-onderdelen. Onze gereedschappen worden voornamelijk geëxporteerd naar de V.S., Europa, Japan en het VK. De diversificatiestrategie en volledige service van JasonMould hebben complimenten gekregen van klanten over de hele wereld.

Onze missie is om onze klanten hoogwaardige vormproducten en -diensten te bieden. We streven ernaar de prijsverwachtingen van onze klanten te overtreffen, kwaliteit en stipte levering. Om onze missie te bereiken, JasonMould:

- Zet zich in om de vaardigheden en efficiëntie van medewerkers voortdurend te verbeteren,

- Biedt onze medewerkers een schone en veilige werkomgeving,

- Upgradet machinetechnologie en ondersteunende apparatuur via een strikt onderhoudsprogramma, en

- Handhaaft de tooling van klanten op het hoogste prestatieniveau

Voor meer informatie over de op maat gemaakte fabrikant van kunststof vormproducten:,bezoek alstublieft https://www.jasonmolding.com/

Aanvraag Contact::

Contactpersoon: James Yuan

Bedrijfsnaam: JasonMould Industrial Company Limited

Adres: LongGang Village,LongXi Town,BoLuo County,HuiZhou-stad,Provincie GuangDong, China

Telefoon: 86-752-6682869

E-mail: [email protected]

Website: https://www.jasonmolding.com