What is a mould? It is a pattern or tool of the product by the means of 注入, 吹く, 排出, 鋳造, 工業生産におけるパンチングなど. 中国の金型産業は、産業構造の調整と産業のアップグレードの実施において満足のいく成果を上げました. The quick development of the mould industry gives hope to many mould enterprises. But it is a pity that Chinese mould industry can not get rid of low-end market positioning. How to speed up the replacement rate of the molds and additional products and develop towards the high-end brands is becoming companies’ objective.. In order to meet the need of the products, there are eight main development trends for the mould.

The first one is that mould products are increasingly larger. This is due to increasingly larger of the parts which are used for the molding of products. 加えて, it is also caused by “a multi-cavity mould” required by the high production efficiency.

The second development trend is that the accuracy of the mould is higher and higher. Ten years ago, the accuracy of the precision mould was about five micrometers. But now the accuracy can achieve two or three micrometers. Some professional manufacturers are making effort to produce the mould whose accuracy will be one micrometer.

第三に, the multi-functional compound mould will be further developed. The new-type mould can not only punch the forming components but also can take on other tasks such as overlying, threading, riveting and locking. 一言で, the requirement for the steel material is higher and higher.

The fourth development trend is that the plastic mould plays a more and more important role in the hot runner mould. Because the hot runner technology can improve the production efficiency and quality and meanwhile save the raw material to some degree, this technology is developed very quickly. The hot runner technology has been adopted by many factories to produce the plastic mould.

Fifthly, some new moulds that adapt to high-pressure injection and molding will be developed with the continuous improvement of plastic molding process.

The sixth one is that the application of standard parts will be more extensive. The application of mold standardization and mould standard parts will greatly affect the mold manufacturing cycle. It can also improve the quality of molds and reduce the manufacturing costs.

Seventhly, the rapid and economic mould will have a promising future. It is the manufacturing era for diversities and short-run. From this point, people can see that the usage cycle of the product will be shortened and meanwhile the diversities will often be changed. 一言で, this so-called rapid and economic mould gains more and more concerns.

The eight development trend is that with the light-weight development of the vehicles and electric motors the die-casting mould will be more and more important. 同時に, because of the complexity and accuracy of the spare parts the requirement for the die-casting mould is higher and higher.

約 ジェイソンモールド インダストリアルカンパニーリミテッド

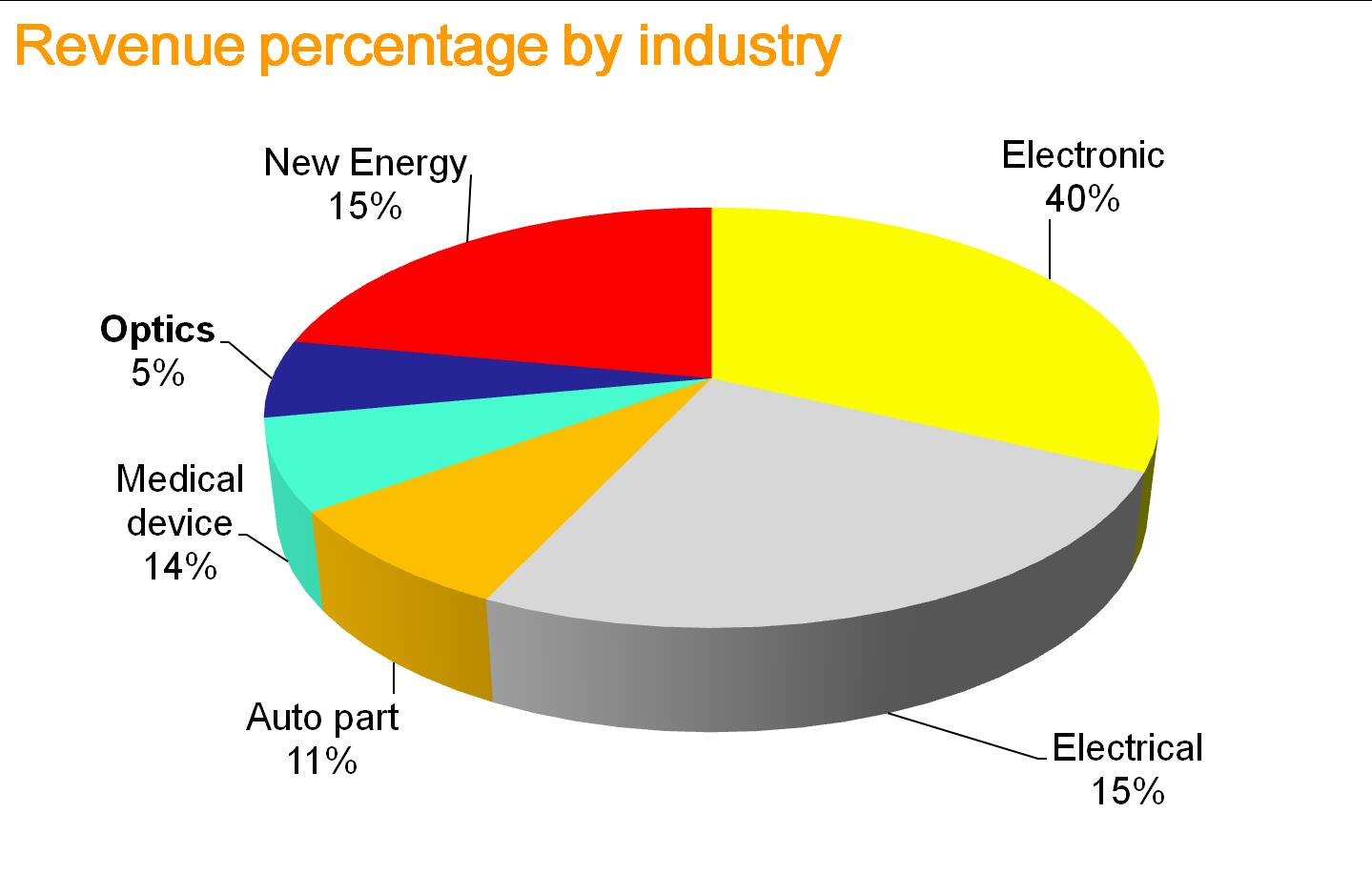

Jasonmouldはプラスチック金型のメーカーです- 射出成形金型, ダイカスト金型, プラスチックブロー成形, 回転成形, 医療用プラスチック射出成形, ツーショットプラスチック射出成形, インサート成形, オーバーモールド, 金属射出成形, マイクロ射出成形, 粉末射出成形, セラミック射出成形, 液体射出成形, ハスキーインジェクションモールディング, 家庭用カビ, 鋳造金型, ダイモールドツール, カスタムモールド, 中国のカビ, ラピッドプロトタイピングツール, プラスチックプロトタイピングツーリング, パンチプレス工具, 携帯電話/携帯電話部品用の金型と工具, 自動車部品, 掃除機, 充電式ツール, 電話, コピー機, コンピューター, マルチメディアスピーカー, および他の多くの電子製品および家電製品. また、プラスチック製品メーカー- プラスチックの部品, プラスチック製の水タンク, プラスチックボール, プラスチック容器, プラスチックバックル, プラスチックアンカー, プラスチックハンガー, プラスチックスプーン, プラスチックパイプフィッティング, プラスチックタンブル, プラスチック製食器, プラスチックのコップ, ペットボトル, プラスチックトレイ, プラスチック化粧品容器, プラスチックケース, プラスチック製の食品容器, プラスチック製の椅子, プラスチックキャップ, プラスチックキャップクロージャー, プラスチックチューブ, プラスチック製の水道管, プラスチック製のノブ, プラスチックチューブ, プラスチック製ユーティリティボックス, プラスチックラックなど.

連絡先:

連絡窓口: ジェームズ・ユアン

会社名: JasonMould Industrial Company Limited

住所: 竜崗村,Long西町,博羅県,恵州市,広東省, 中国

電話: 86-752-6682869

Eメール: [email protected]

Webサイト: https://www.jasonmolding.com