Failure often occurs in the use of 金型, 実際の観点から, いくつかの故障モードに焦点を当てます. 5つの主なタイプがあります:

- 塑性変形の失敗

主な理由は、金型材料の強度レベルが高くないことです; または熱処理プロセスが正しくありません, 鋼の最高の強度と靭性を達成できない; ダイの不適切な使用により局所的な過負荷が発生する; for hot-working mold softening at high temperature will also lead to mold thermoplastic deformation failure. Deformation failure can lead to deformation of the mold and ultimately affect the quality of the forging.

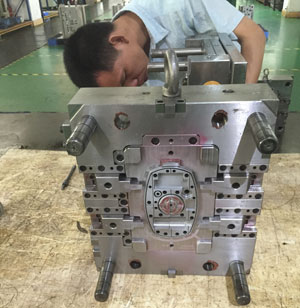

金型製作

- 2.Moldswear failure

The basic reason for the failure of the mold is the friction between the mold and the billet. But the specific form of wear and the wear process are related to many factors, such as the pressure, 温度, deformation speed and lubrication condition of the mold in the working process. For hot working mold, the wear resistance decreases due to the softening of cavity surface by high temperature, and the oxide scale itself plays an abrasive role, which determines that the wear process is more complex. The wear failure of the mold mainly results in the wear of the forging mold and the accuracy of the forging.

- Fatigue failure of molds

The ultimate cause of fatigue failure is the stress concentration and cyclic load. Although the load on the mold is sometimes significantly lower than its yield strength, due to local stress concentration, under low load, microcracks still form at the stress concentration. The dies are usually in high strength and low plasticity. When the micro-cracks are formed, the micro-cracks are easy to propagate and ultimately lead to fatigue fracture under the cyclic loading of the dies.

- Cold and hot fatigue failure of molds

For the hot working mold, the surface temperature of the mold often rises to 600 〜 900 C because of the interaction with the hot blank. In order not to reduce the strength of the mold, the mold must be sprayed with a coolant to cool it down. This cycle is a process of rapid cooling and rapid heating on the surface of the mold, and a considerable cyclic thermal stress is accumulated on the surface of the mold. The stress is finally released in the form of cold and hot fatigue, forming cold and hot fatigue cracks. As for high temperature oxidation, corrosion of coolant and friction between mould and high temperature billet, the process of cold and hot fatigue is accelerated.

- Failure under the influence of comprehensive factors

The working conditions of the mold are intricate, so the occurrence of damage events occur from time to time. Once the damage is caused, they may promote each other, and ultimately accelerate the failure of the mold.

JasonMould Industrial Company Limited, に設立されました 2010, 中国の大手射出成形メーカーです. JasonMould は、家電製品のプラスチック金型の製造を専門としています。, 医療機器, 電子機器, 安全装置および監視システム.

会社は終わった 15000 平方メートル工場. 異なる機械と専門知識を持つプラスチック射出成形部門と, JasonMould は、小型で精密な携帯電話部品から自動車部品と同じくらい大きな部品まで、ツールを提供しています。. 当社の工具は主に米国に輸出されています。, ヨーロッパ, 日本と英国. JasonMould の多角化戦略とフルサービスは、世界中の顧客から称賛を集めています。.

私たちの使命は、お客様に高品質の成形製品とサービスを提供することです. お客様の価格に対する期待を超えることを目指しています, 品質と納期厳守. 私たちの使命を達成するために, ジェイソンモールド:

- 従業員のスキルと効率を継続的に改善することを約束します,

- 従業員に清潔で安全な作業環境を提供します,

- 厳格なメンテナンスプログラムにより、機械技術とサポート機器をアップグレードします, そして

- お客様のツールを最高のパフォーマンスに維持します

プラスチック成形製品のカスタムメーカーの詳細については,来てください https://www.jasonmolding.com/

お問い合わせ先:

連絡窓口: ジェームズ・ユアン

会社名: JasonMould Industrial Company Limited

住所: 竜崗村,Long西町,博羅県,恵州市,広東省, 中国

電話: 86-752-6682869

Eメール: [email protected]

Webサイト: https://www.jasonmolding.com