- シングルパーティング表面射出成形金型を開いたとき, 可動ダイと固定ダイが分離されています, プラスチック部品を取り出します, これは、シングルパーティング表面モールドとダブルプレートモールドと呼ばれます. It is the simplest and most basic form of injection mould. It can be designed as a single cavity injection mould or a multi-cavity injection mould according to the need. It is the most widely used injection mold.

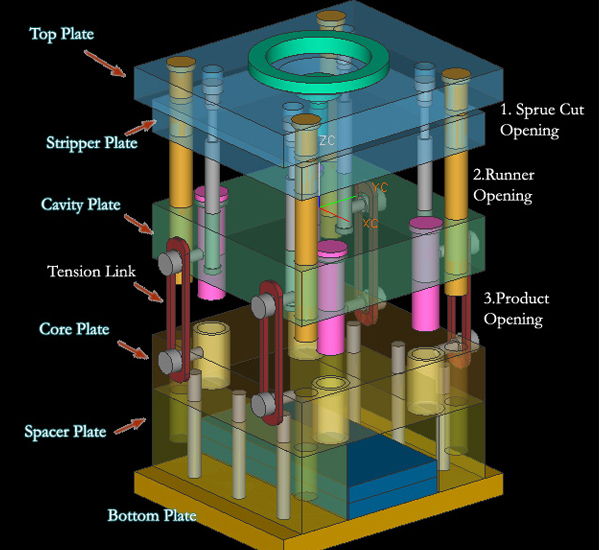

- The double parting surface injection mould has two parting surfaces. Compared with the single parting surface injection mould, the double parting surface injection mould adds a movable middle plate (also called movable gate board) in the fixed part of the mould. It has a gate, ランナー, and other parts and components needed for a fixed mold, so it is also called a three-plate injection mould (moving template, middle plate, fixed template). It is often used for injection molds with single or multiple cavities that point gate feed, when opening a mold, The intermediate plate is separated from the fixed template at a fixed distance on the guide column of the die to remove the castable system between the two templates. The injection mould with double parting surface is complex in structure, high in manufacturing cost and difficult in parts processing, so it is not generally used in the molding of large or super large plastic products.

- Injection molds with lateral parting and core-pulling mechanism. When plastic parts have side holes or side recesses, lateral moving cores or sliders should be used. After injection molding, the dynamic die moves a distance down first, then the inclined section of the bending pin fixed on the fixed template forces the slider to move outwards. 同時に, the push rod of the demoulding mechanism pushes the push plate to make the plastic part take off from the core.

- Because of some special structure of plastic parts, injection molds with movable forming parts require movable molding parts, such as movable punch, movable concave die, movable insert, movable thread core or ring, NS. During demoulding, you can move out of the mold together with the plastic parts, and then separate from the plastic parts.

- For plastic parts with screw threads, the injection mould can be automatically unthreaded by setting a thread core or ring that can be rotated on the mould, using the opening action or the rotating mechanism of the injection molding machine, or setting up a special transmission device. Drive screw thread core or thread ring rotation, so as to remove plastic parts.

- The injection mould without runner is the method of adiabatic heating of the runner, which keeps the plastic melt from the one cavity of the nozzle of the injection molding machine, and makes the mold take out the plastic parts without the pouring system solidification. The former is called adiabatic injection mold, the latter is called hot runner injection mold.

- The right angle injection mould is only suitable for the angular injection molding machine, which is different from other injection molds in that the feeding direction of the mould is perpendicular to the opening and closing direction of the mould. His main channel is set on both sides of the moving, fixed parting surface, and its cross section is usually the same, which is different from the mold used in other injection molding machines, the end of the main channel. In order to prevent the abrasion and deformation of the nozzle and the main inlet of the injection molding machine, replaceable runner inserts can be set up.

- ほとんどの射出成形金型, the demoulding device is installed on the side of the moving mold, which is advantageous to the work of ejection device in the opening and closing system of the injection molding machine. In actual production, because some plastic parts are limited by the shape, it is better to leave the plastic parts on the one side of the fixed mold, so that the plastic parts can be removed from the mold, so the demoulding mechanism must be set on the side of the fixed mold.

Jasonmouldはプラスチック金型のメーカーです- 射出成形金型, ダイカスト金型, プラスチックブロー成形, 回転成形, 医療用プラスチック射出成形, ツーショットプラスチック射出成形, インサート成形, オーバーモールド, 金属射出成形, マイクロ射出成形, 粉末射出成形, セラミック射出成形, 液体射出成形, ハスキーインジェクションモールディング, 家庭用カビ, 鋳造金型, ダイモールドツール, カスタムモールド, 中国のカビ, ラピッドプロトタイピングツール, プラスチックプロトタイピングツーリング, パンチプレス工具, 携帯電話/携帯電話部品用の金型と工具, 自動車部品, 掃除機, 充電式ツール, 電話, コピー機, コンピューター, マルチメディアスピーカー, および他の多くの電子製品および家電製品. また、プラスチック製品メーカー- プラスチックの部品, プラスチック製の水タンク, プラスチックボール, プラスチック容器, プラスチックバックル, プラスチックアンカー, プラスチックハンガー, プラスチックスプーン, プラスチックパイプフィッティング, プラスチックタンブル, プラスチック製食器, プラスチックのコップ, ペットボトル, プラスチックトレイ, プラスチック化粧品容器, プラスチックケース, プラスチック製の食品容器, プラスチック製の椅子, プラスチックキャップ, プラスチックキャップクロージャー, プラスチックチューブ, プラスチック製の水道管, プラスチック製のノブ, プラスチックチューブ, プラスチック製ユーティリティボックス, プラスチックラックなど.

Jasonmouldはプラスチック金型のメーカーです- 射出成形金型, ダイカスト金型, プラスチックブロー成形, 回転成形, 医療用プラスチック射出成形, ツーショットプラスチック射出成形, インサート成形, オーバーモールド, 金属射出成形, マイクロ射出成形, 粉末射出成形, セラミック射出成形, 液体射出成形, ハスキーインジェクションモールディング, 家庭用カビ, 鋳造金型, ダイモールドツール, カスタムモールド, 中国のカビ, ラピッドプロトタイピングツール, プラスチックプロトタイピングツーリング, パンチプレス工具, 携帯電話/携帯電話部品用の金型と工具, 自動車部品, 掃除機, 充電式ツール, 電話, コピー機, コンピューター, マルチメディアスピーカー, および他の多くの電子製品および家電製品. また、プラスチック製品メーカー- プラスチックの部品, プラスチック製の水タンク, プラスチックボール, プラスチック容器, プラスチックバックル, プラスチックアンカー, プラスチックハンガー, プラスチックスプーン, プラスチックパイプフィッティング, プラスチックタンブル, プラスチック製食器, プラスチックのコップ, ペットボトル, プラスチックトレイ, プラスチック化粧品容器, プラスチックケース, プラスチック製の食品容器, プラスチック製の椅子, プラスチックキャップ, プラスチックキャップクロージャー, プラスチックチューブ, プラスチック製の水道管, プラスチック製のノブ, プラスチックチューブ, プラスチック製ユーティリティボックス, プラスチックラックなど.連絡先:

連絡窓口: ジェームズ・ユアン

会社名: JasonMould Industrial Company Limited

住所: 竜崗村,Long西町,博羅県,恵州市,広東省, 中国

電話: 86-752-6682869

Eメール: [email protected]

Webサイト: https://www.jasonmolding.com

18

4月