さまざまな成形方法による, さまざまなプロセス要件に対応するさまざまなタイプのプラスチック加工金型を分割できます, 主に射出成形金型を含む, 押出型, プラスチックサクションモールド, 高発泡ポリスチレンモールドなど.

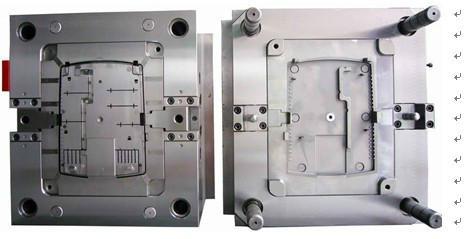

1.プラスチック射出成形金型

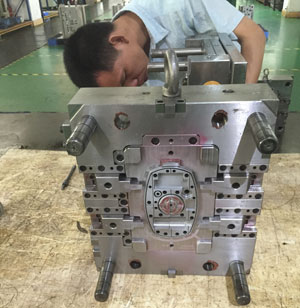

It is mainly a kind of molding mould which is widely used in the production of thermoplastic parts. The corresponding processing equipment for plastic injection mould is plastic injection molding machine. The plastics are first heated and melted in the bottom heating drum of the injection machine.Then the injection machine screw or plunger push through the injection machine nozzles and mold gating system into the mold cavity plastic cooling hardening molding mold to get products.The structure is usually composed of molding parts, gating systems, guide parts, push mechanism, 温度調節システム, 排気装置, supporting parts and so on.The main materials are carbon structural steel, 炭素工具鋼, 合金工具鋼, high speed steel and so on.The injection molding process is usually only suitable for the production of thermoplastics products. The plastic products produced by the injection molding process are very extensive, ranging from daily necessities to all kinds of complicated machinery and electrical appliances.The parts of vehicle are molded by injection mould, which is the most widely used processing method in plastic production.

2.Plastic pressure-plastic mould

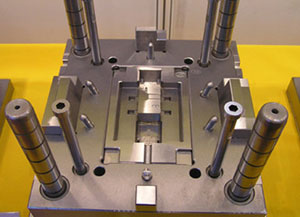

Including compression molding and injection molding two types of structural die.They are mainly used to form thermosetting plastics, the corresponding equipment is a pressure molding machine.Compression molding method according to the plastic characteristics, the mould is heated to the molding temperature (一般的 103 °-108 °), then the measured compression and plastic powder is put into the mold cavity and feeding chamber to close the mold, and the plastic shows a softening viscous flow under the action of high heat and high pressure.After a certain period of time, solidify the shape of the desired product.Different from the compression molding, there is a separate feeding chamber, the mold is closed before forming, the preheating of the plastic in the feeding chamber is viscous, and the plastic is extruded into the die cavity under the action of pressure and hardened.Compression moulds are also used to form some special thermoplastic such as hard to melt thermoplastic (such as polyfluoroethylene) 空白 (cold pressing molding, high optical properties of resin lens, slightly foaming nitrate cellulose steering wheel and so on.The molding die is mainly made up of cavity, feeding cavity, 誘導機構, pushing parts, heating system and so on.Injection die is widely used in packaging electrical components.The material used in the manufacture of the pressure-plastic mould is basically the same as the injection mould.

3.Plastic extrusion mould

A kind of mould used to produce continuous plastic products, also called extrusion head, パイプの加工に広く使用されています, バー, single filament, シート, 映画, ワイヤーとケーブルのコーティング, profile, etc.The corresponding production equipment is the plastic extruder. The principle is that the solid plastic is melted and plasticized under the condition of heating and extruder’s screw rotation and pressure, and the continuous plastic products with the same cross section and die shape are made through the die with a specific shape.The main manufacturing materials are carbon structural steel, alloy tools, and some extrusion dies will insert diamond and other wear-resistant materials on the parts that need wear resistance.Extrusion process is usually only suitable for the production of thermoplastic products, and its structure is obviously different from that of injection molds and compression molds.

4.Plastic blow mould

It is a mold used to form hollow products of plastic containers (飲料ボトルなど, 日用化学薬品およびその他の包装容器). According to the principle of technology, the main forms of blow molding are extrusion blow molding, injection blow molding hollow molding.Injection extended blow molding hollow molding (commonly known as “injection-pull blowing”), multi-layer blow-molding hollow molding, sheet blow-molding hollow molding, etc.The equipment corresponding to blow molding of hollow products is usually called plastic blow molding machine, and blow molding is only suitable for the production of thermoplastic products.Blow mold structure is relatively simple, the materials used to make more carbon.

5.Plastic suction mould

It is a kind of mould which uses plastic sheet or sheet as raw material to form some simple plastic products. The principle is that the plastic plate fixed on the die or punch is made by using vacuum blooming method or compressed air forming method.In the case of heating and softening deformation and sticking to the mold cavity to obtain the necessary molding products, mainly used in some daily necessities, 食べ物, toys packaging products production.Because of the low pressure during molding, the mould materials are made of cast aluminum or non-metallic materials, そして構造は比較的シンプルです.

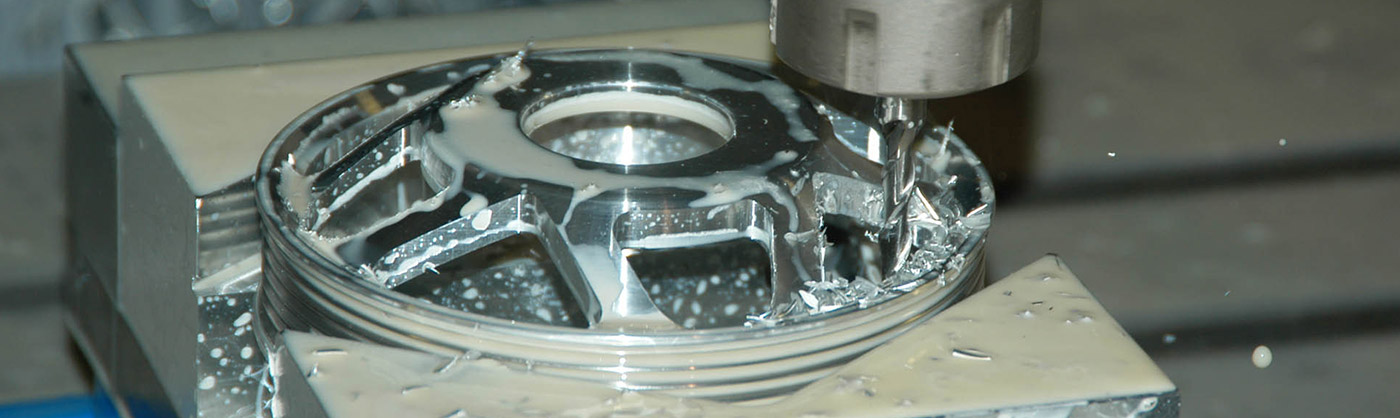

金型製作

6.Plastic high foaming polystyrene mould

Is the application of expandable polystyrene (bead material consisting of polystyrene and foaming agent) a mold foam packing material to forming all kinds of raw materials required for the shape. The principle is to die in the internal energy of steam into polystyrene molding, including simple manual type foam mold molds and hydraulic straight through processing of two types of main for the production of industrial packaging products. Die manufacturing such materials are cast aluminum, 真空鋳造を提供します, bronze and so on.

JasonMould Industrial CompanyLimitedについて

Jasonmouldはプラスチック金型のメーカーです- 射出成形金型, ダイカスト金型, プラスチックブロー成形, 回転成形, 医療 プラスチック射出成形, ツーショット プラスチック射出成形, インサート成形, オーバーモールド, 金属射出成形, マイクロ射出成形, 粉末射出成形, セラミック射出成形, 液体射出成形, ハスキーインジェクションモールディング, 家庭用カビ, 鋳造金型, ダイモールドツール, カスタムモールド, 中国のカビ, ラピッドプロトタイピングツール, プラスチックプロトタイピングツーリング, パンチプレス工具, 携帯電話/携帯電話部品用の金型と工具, 自動車部品, 掃除機, 充電式ツール, 電話, コピー機, コンピューター, マルチメディアスピーカー, および他の多くの電子製品および家電製品. また、プラスチック製品メーカー- プラスチックの部品, プラスチック製の水タンク, プラスチックボール, プラスチック容器, プラスチックバックル, プラスチックアンカー, プラスチックハンガー, プラスチックスプーン, プラスチックパイプフィッティング, プラスチックタンブル, プラスチック製食器, プラスチックのコップ, ペットボトル, プラスチックトレイ, プラスチック化粧品容器, プラスチックケース, プラスチック製の食品容器, プラスチック製の椅子, プラスチックキャップ, プラスチックキャップクロージャー, プラスチックチューブ, プラスチック製の水道管, プラスチック製のノブ, プラスチックチューブ, プラスチック製ユーティリティボックス, プラスチックラックなど.

連絡先:

人: ジェームズ・ユアン

会社: JasonMould Industrial Company Limited

追加:LongGangVillage,LongXiTown,BoLuoCounty,HuiZhouCity,広東省, 中国

電話: 86-752-6682869

Eメール: [email protected]

地点:https://www.jasonmolding.com/custom-injection-molding/